Popular Design for Ceramic Nozzle - OEM/ODM Factory China Paper Machine Ceramic Dewater Hydrofoil Vacuum Suction Box – Guiyuan

Short Description:

Product Detail

Product Tags

Related Video

Feedback (2)

Popular Design for Ceramic Nozzle - OEM/ODM Factory China Paper Machine Ceramic Dewater Hydrofoil Vacuum Suction Box – Guiyuan Detail:

Fast and superior quotations, informed advisers to help you choose the correct solution that suits all your needs, a short generation time, responsible quality handle and unique products and services for paying and shipping affairs for OEM/ODM Factory China Paper Machine Ceramic Dewater Hydrofoil Vacuum Suction Box, Your inquiry might be extremely welcomed plus a win-win prosperous development are what we’ve been expecting.

Fast and superior quotations, informed advisers to help you choose the correct solution that suits all your needs, a short generation time, responsible quality handle and unique products and services for paying and shipping affairs for China Hydrofoil, Dewater Element, To get more information about us as well as see all our products and solutions, you should visit our website. To get more information please feel free to let us know. Thank you very much and wish your business always be great!

Product Details

Compared to the the plastic dewatering elements, ceramic covers are suitalbe for all range of paper machine speed. Due to its special material performance, the ceramic covers have much longer lifetime. With unique composit system and structure that have been develped, our ceramic cover has been proved a better drainage, formation, refinning, smoothness after application.

Product Description

The wet end of the fourdrinier machine is one of the determining factors for performance and quality of the end paper. Once the paper sheet caught on top side of the fabric, the fiber interwove and boud together. Right at this point, the physical property of the sheet has been formed.

Compared to the HDPE plastic material, ceramic drainage panel has better performance in strength, thermal shock resisttance, stability, toughness, wear resisttance, and fatigue and not easy deformation. After changing into ceramic covers, the wire table’ straightness, flatness and finess improves.

our company repeatedly improves our products quality to meet the desires of higher speed paper machine and further focuses on safety, reliability, environmental requirements, and innovation of Dewatering Element for Paper Mill, we play a leading role in supplying clients with high-quality items.

With good wear resisttance and lower coefficient of fiction, our products are able to prolong the lifetime of the fabric up to 125 days. Total costs have been saved dramatically.

We have been adhering to the philosophy of “attracting customers with the best items and excellent service”. We can provide engineering designs according to various paper machine type and paper grade to guarantee good dehydration effects. We welcome customers, business associations and friends from all parts of the world to contact us and seek cooperation for mutual benefits.

Primary Competitive Advantage

• Low friction coefficient

• Stable structure

• High-strength matrix of fiber glass/carbon fiber

• Easy to replace

• Low adhesive rate for mixtures

• Movable bar

• Effectively protect forming wire

• Long service life

Quick Details

|

Material |

Bulk Density |

Bend strength |

Toughness |

Hardness |

Thermal shock resistance |

Heat conductivity |

|

(g/cm3) |

(Mpa) |

(Mpa.M2/1) |

(Kg/mm2) |

(10o/C) |

(W/mk) |

|

| Sicer-A | 3.81-3.84 | 360-400 | 4.0-5.0 | 1350-1450 | 7.0-8.0 | 18-20 |

| Sicer-SubA | 3.86-3.88 | 380-420 | 5.0-6.0 | 1450-1530 | 7.0-8.0 | 20-25 |

| Sicer-AZ | 5.65-5.75 | 900-1100 | 5.0-6.0 | 1400-1500 | 9.0-10.0 | 3-4 |

| Sicer-ZROX | 5.70-5.75 | 900-1100 | 8.0-9.0 | 1200~1250 | 9.0-10.0 | 1-2 |

| Sicer-ASC | 3.05-3.10 | 350-400 | 4.0-4.5 | 2000~2400 | 4.0-4.5 | 80–90 |

| Sicer-SN | 3.05-3.20 | 650-750 | 6.0-6.7 | 1650-1750 | 2.5-3.0 | 30–50 |

Dewatering Elements- AlOx

High quality aluminium oxide in submiron 99% can be applied to wide range of machine speed with best cost effectivness.

Max. Length ~9000mm

Good wear ressistance

Lower roughness

Wide application

Low maintenance

Cost effective

Applied for : full wire talbe under 800m/min

Gravitation dewatering box under 1200m/min

Dewatering Elements-SN

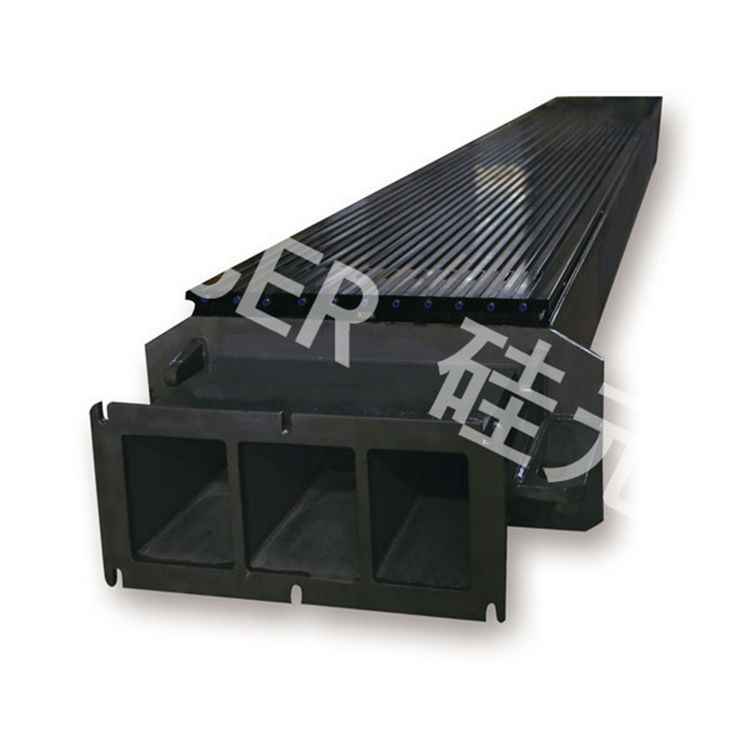

SICER-SN dewatering elements used high strength material as base, covered with high quality ceramics of wear-resisttant SiN. Its perfect precision and good machining quality ensured the safty installation and replacement. By seamless bonding, no piano key occurred to the cover.

High grade Si3N4 material

Long term reliable performance

High wear ressistance

Consistant dewatering

Applied for: vacuum cover or press section under 1500m/min

Dewatering Elements- ZA

Dewatering Elements-ZROx

Better protection of the felt and prolong its lifetime

Lower coefficient of friction

Smothness and improved surface quality

Applifed for: press section under the machine speed of 1000m/min

Dewatering Elements-AZ

Matrial content: Al2O3 and ZirO2

Long term reliable performance

High wear ressistance

Efficient Drainage

Lower energy consumption

Applied for: vacuum cover or press section under 1500m/min

Fast and superior quotations, informed advisers to help you choose the correct solution that suits all your needs, a short generation time, responsible quality handle and unique products and services for paying and shipping affairs for OEM/ODM Factory China Paper Machine Ceramic Dewater Hydrofoil Vacuum Suction Box, Your inquiry might be extremely welcomed plus a win-win prosperous development are what we’ve been expecting.

OEM/ODM Factory China Hydrofoil, Dewater Element, To get more information about us as well as see all our products and solutions, you should visit our website. To get more information please feel free to let us know. Thank you very much and wish your business always be great!

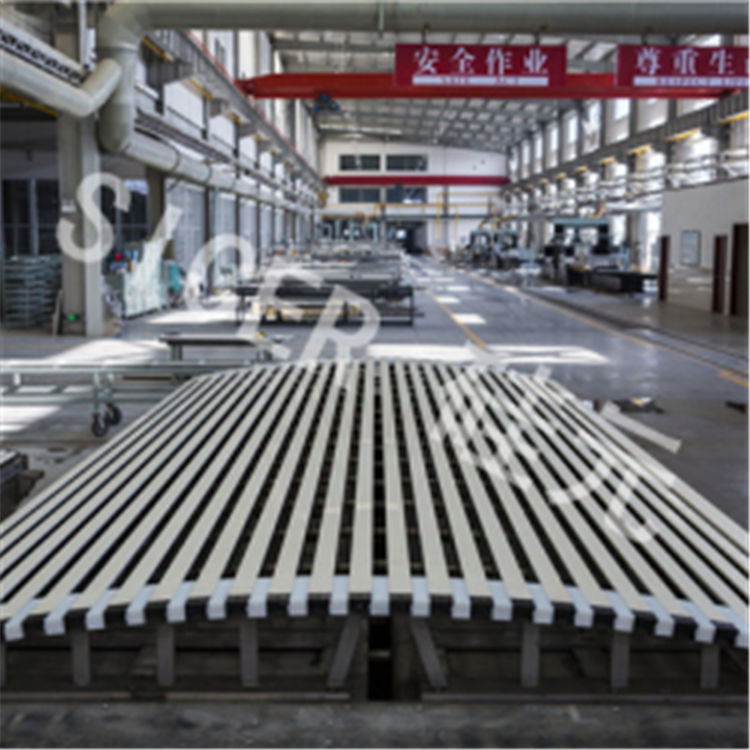

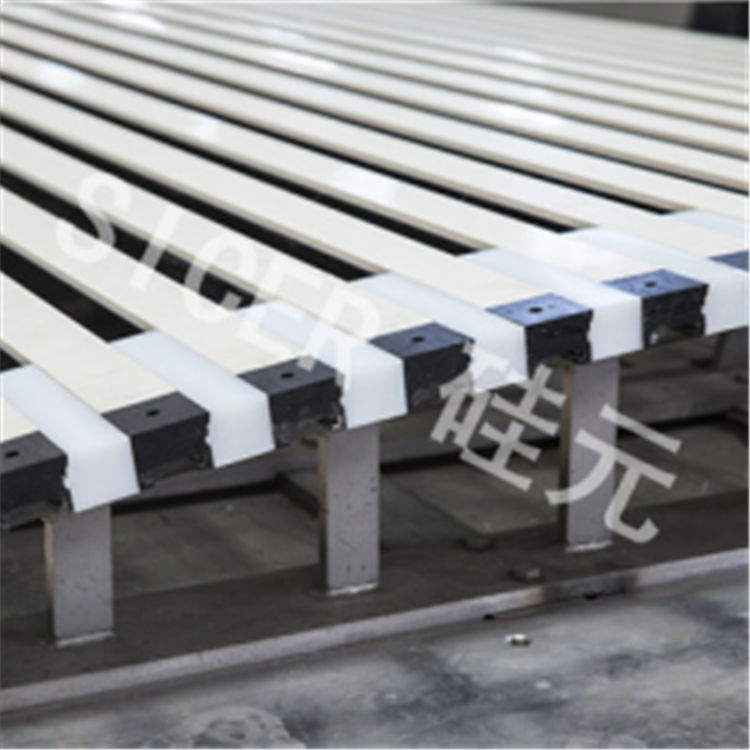

Product detail pictures:

Related Product Guide:

To create more benefit for buyers is our business philosophy; shopper growing is our working chase for Popular Design for Ceramic Nozzle - OEM/ODM Factory China Paper Machine Ceramic Dewater Hydrofoil Vacuum Suction Box – Guiyuan, The product will supply to all over the world, such as: Hungary, Iran, Guatemala, Our domestic website's generated over 50, 000 purchasing orders every year and quite successful for internet shopping in Japan. We would be happy to have an opportunity to do business with your company. Looking forward to receiving your message !

Wide range, good quality, reasonable prices and good service, advanced equipment, excellent talents and continuously strengthened technology forces,a nice business partner.