Congrats!! Newly Built Project!!

Located in Zhejiang, China, a newly built project is ready for satr up.

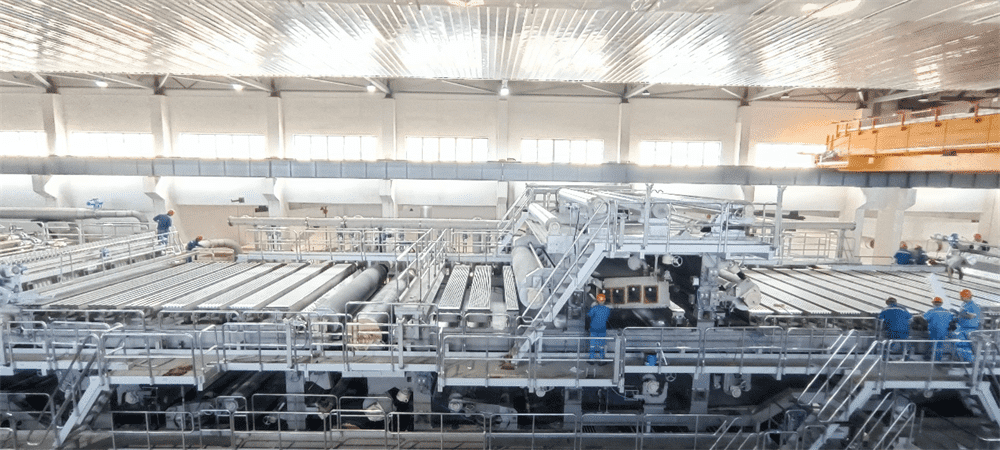

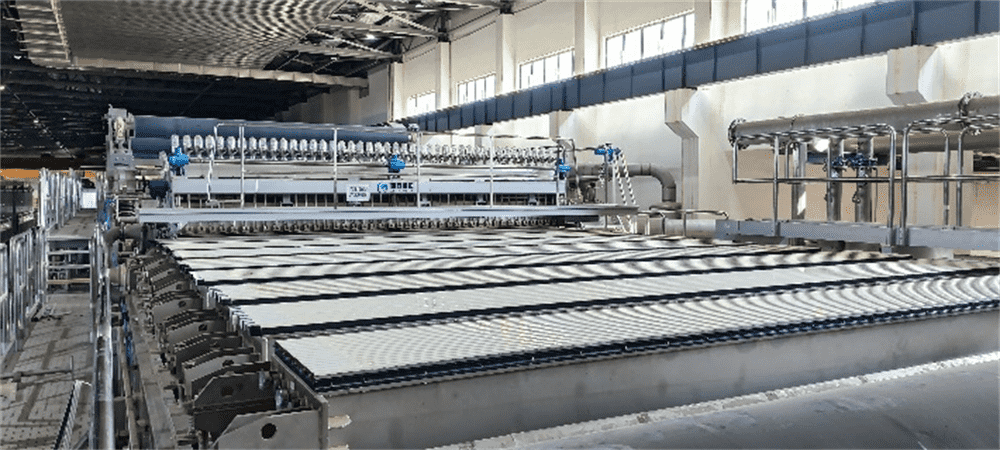

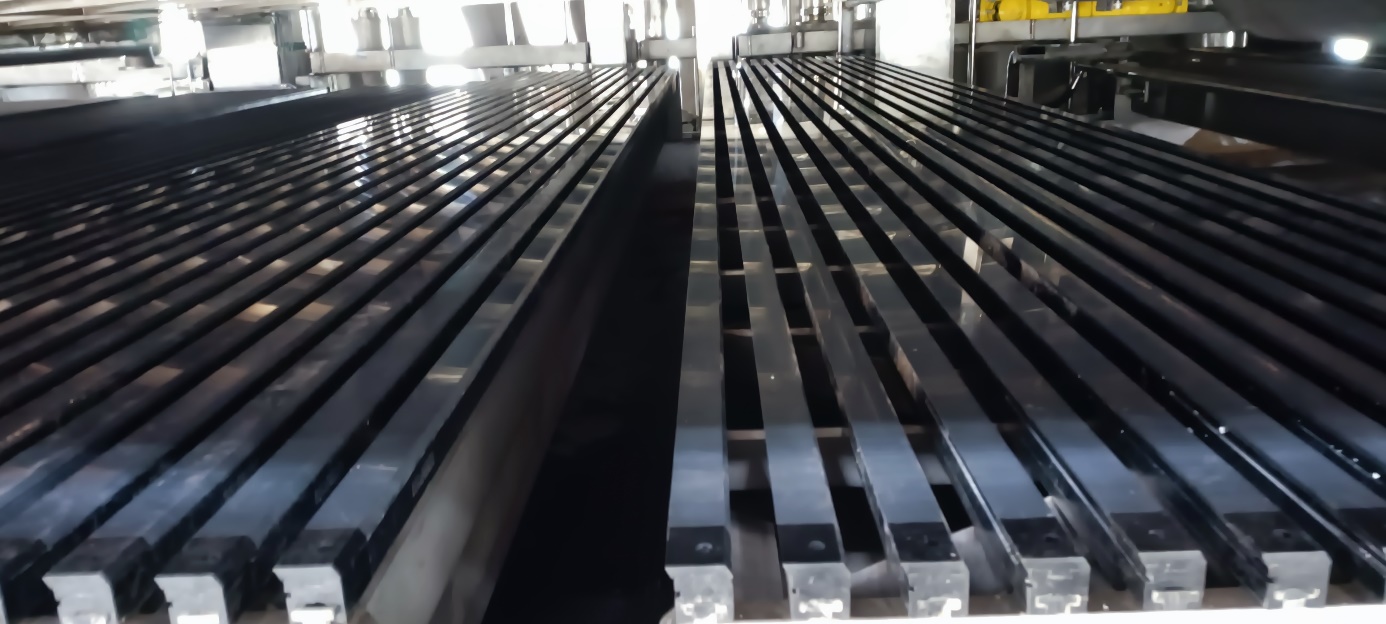

We are proudly annouce that SICER has installed full set of ceramic dewatering elemtns for wire section of the new machine. The is a machine 5600/650, making corrugated cardboard. For such a big machine, it surely is a hard work of installation. When we are at site, it’s thrilled to see the well done work and expect for the early running.

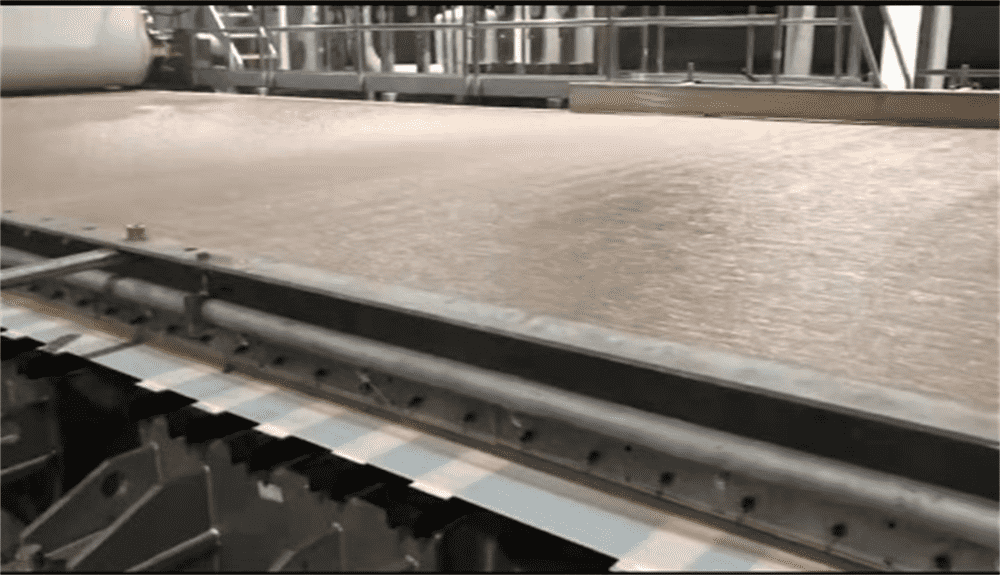

With high purity 99 alumina, the dewatering elements will performed more smoothly, with very small wear resisttance and corrosion. As a reslut, it will save more energy and support the fabics with longer lifetime. It’s surely the first choice for such a paper machine. Ceramic Dewatering Elements usually can be used as long as 5-10 years without much maintainence. Compared to its equivalence, like UHMWPE, they don't need to change frequently, which will provide stable performance and save a lot of lobors. It should be invest a lot at first, while, in the long run, it’s really cost-efficient and worth the value.

SICER, since 1958, has been doing ceramics and delevoped to be the leading manufactuer in the paper machine industry, specificly in forming board, hydrofoil, formation box, Low vacuum box, High vacuum box, and uhle box, etc. We can supply ceramic dewatering elements as long as 9 meters.

If you interest, please check more in our PROJECT.

New Project Announcement!

Congrats on the newly build paper machine project for N R Agarwal Industries Limited PM5 entering into errection.

N R Agarwal Industries Limited(NRAIL), Established in 1993, Headquartered in Mumbai (India), has a total manufacturing capacity of 354000 TPA paper as on current date, serving with its high-quality paper products both domestic and international markets.

NRAIL has developed to be one of the top manufacturers in the field of recycled paper especially for duplex boards, writing and printing papers, copier and newsprint.

It was a great pleasure to witness NRAIL’s quick growth and big success. And it was a great honor for us(SICER) to joinning the PM 5 project with supplying the ceramic dewatering elements and all the SS304 boxes. For the wire part, there are four layers with trim width of 3750mm filled with 99 alumina, Zirconia and SiN covers.

With consistent efforts and development, SICER has been devoted to be a dewatering elements specialist for mid and high paper machine speed. We are expecting for more close cooperation with customers home and aboad and provide improving quality and best service.

Wire Table Ceramic Maintenance in Quzhou Xianhe Crop.

At the beginning of 2022, the pandemic Omicron has hit numerous places of China, which bring us much troubles for the on-site service. Confirmed cases and asymptomatic cases of COVID-19 have been reported in Zibo. The epidemic prevention and control work is facing challenge. Meanwhile, we received a special request for field installation of dewatering elements. In order to make sure paper machine’s startup in time, SICER’s service team drive to customer’s paper mill which is located in Quzhou without any delay.

Under the epidemic wreathing, various prevention measures have been taken to fight against the virus, and there are also many traffic regulations that blocks the way to customer’s mill, XIANHE Crop.

XIANHE Crop is a company providing high-quality special paper products, including tobacco paper, home decoration, business communication and anti-counterfeiting, food and medical packaging, label release, electrical and industrial paper, etc. Its annual output is more than 820,000 tons. We supplied full set of dewatering elements for their paper mill. And every year we pay a visit for the field service for maintenance and renew the ceramics.

Although we are facing new wave of COVID-19, we still work hardest and put our all into this business. It’s been a long way to fight against the epidemic and we hope everyone could join hands to overcome the obstacles.

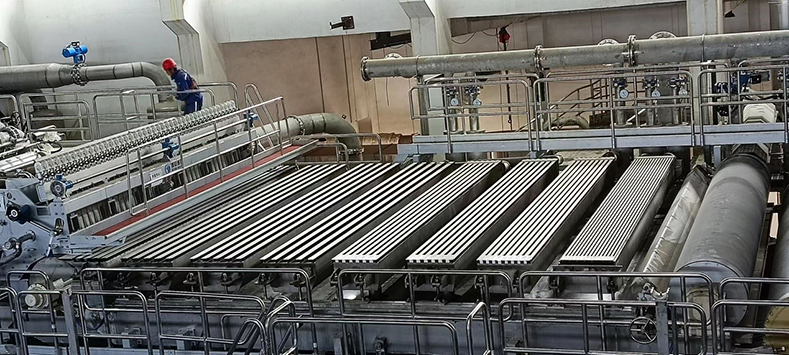

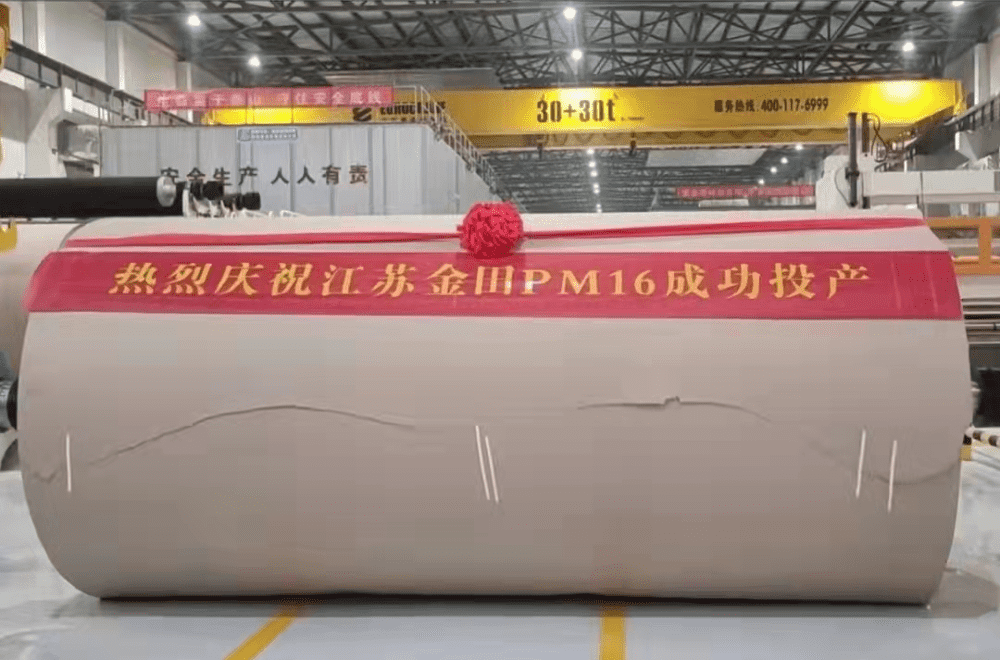

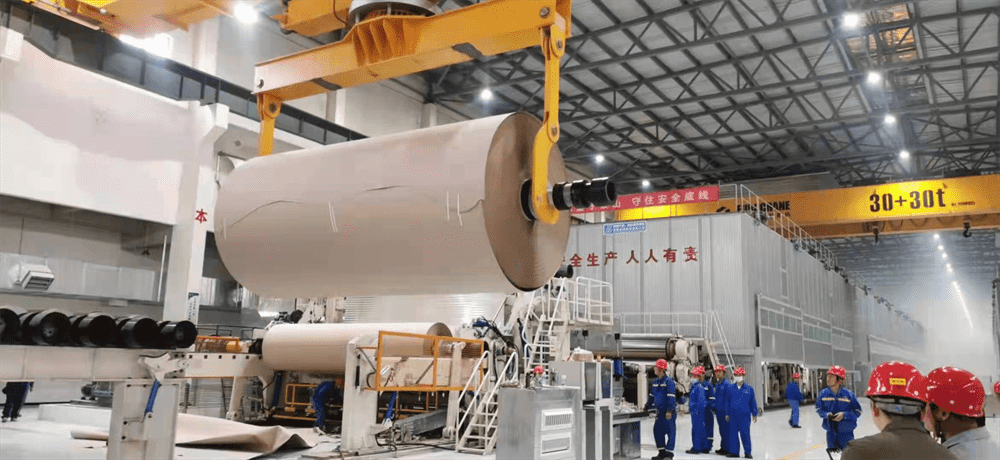

Two New Project for Jintian Paper in 4800/500 and 4800/750

Congratulate to the successful startup of the new paper machine project of Jintian Paper(Jiangsu). This project is followed by the Jintian Paper(Dongguan) and Jintian Paper(Sichuan) over last years. With output of 1000 tons/day, there contains two machines with 4800mm trim width, one designed to 500m/min, and the other 750m/min. The Paper mahcine was built by Hangzhou North Star Light Industry Machinery Co., Ltd. and for the wire section, We(SICER) provided the full set of dewatering elements.

After the trail running in Otc., we reveived customer’s satisfication for the performance of our dewatering elements. The dewatering result and energy saving have been fully reached the expectation. As a result, the smooth running in wire section provide effective support for the following procedures.

Jintian Paper, established in 2003, with three production area in Dongguan, Jiangsu, Sichuan, has become the largest production base in Asia for grey board. Thanks for our customer’s long-term trust and cooperation. With joint efforts, we will continue to provide the best quatlity products and best sevice for customers home and abroad.

Henan Yadu: newly build project 5400/650

Paper making industry has been a conventional industry and Qinyang is a well known city in China that lead in paper making. For the past decade, its permissive development mode has caused huge pressure on environment protection. While, after years of efforts on the equipment’ updation and greening manufacturing, we have seen a quality improvement in full field around. Thus, with sclale, green, high-end in mind, Henan Yadu paper mill has invested numerous technological devices for effective utilization and environmental innovation.

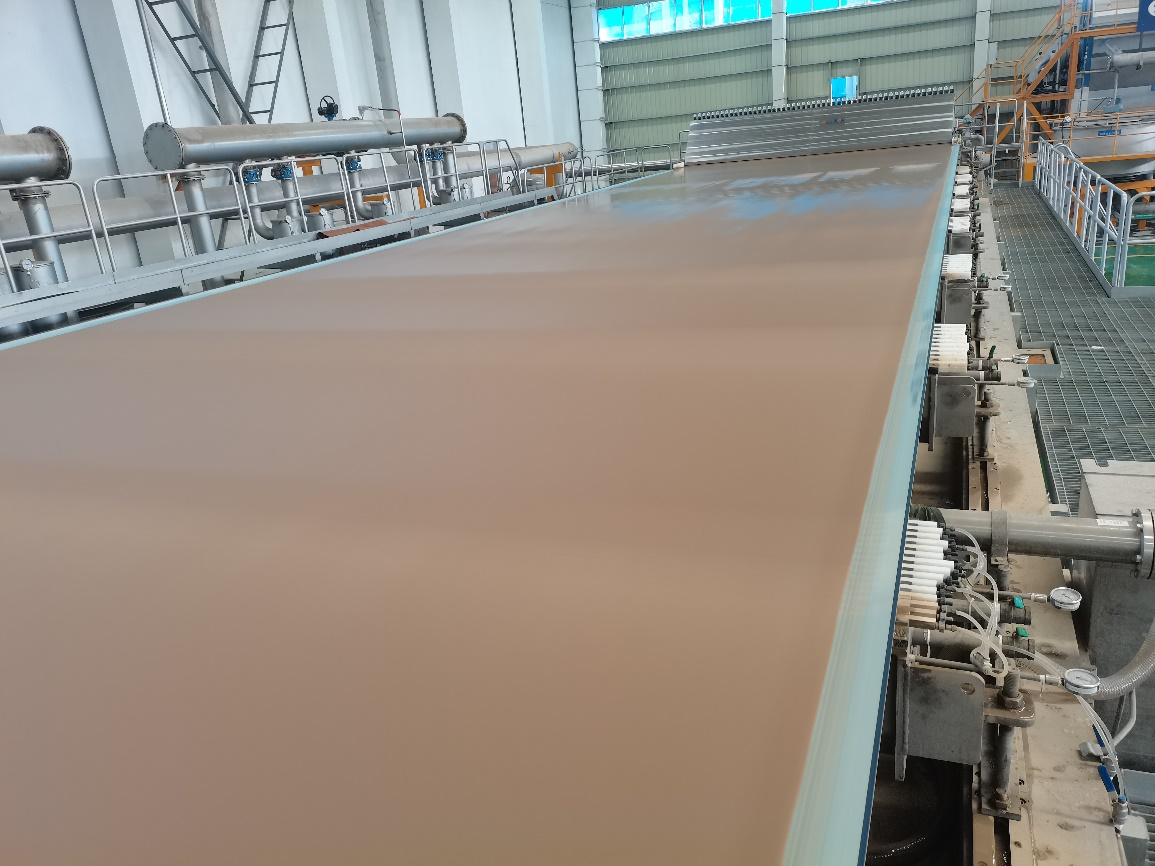

The new paper machine line that finished is for high strength corrugated paper with output of 150,000 tons. The whole paper machine is 121 meters long with designed speed of 650mpm and width of 5400mm. This project’s successful startup made this paper machine became the biggest in this area with longest width, highest speed.

SICER has provided full set of dewatering elements for this paper machine. As forming section is the “heart” of whole machine, the formation of pulp and dewtering performance have always been the biggest concern. With our high quality ceramic dewatering elements of Sub-micro 99% alumina, we supplied forming board box, hydrofoil, formation box, low vacuum box, high vacuum box and so on. The past decade has seen SICER's dewatering equipment technology growing by leaps and bounds, especially on the energy saving and lifetime of the ceramics. With great deal of newly build project experiences, we are fully able to make the customized design for paper machines in different speed and paper type. After adopting intelligent, cost-effective and sustainable process for our production, the best quality products has been also guaranteed.

Vietnam Miza 4800/550 Multi-wire paper machine successfully started up and rolled.

On April 28, 2021, Vietnam Miza 4800/550 Multi-wire paper machine successfully started up and rolled.

The contract for this project was concluded in March, 2019 and all the ceramics have been shipped at customer’s mill in Sep. Later, due to the pandemic, this project has been laid asid for sevral months. Since the epidemic outbreak been controlled, we resume production in an orderly manner. Thanks to the widely and effectively vaccination against the virus, our technician travels a long way to Hanoi for the installation.

Congratulations to Miza, Vietnam and Huazhang Technology, the general contractor of the project.

This paper machine is making Kraft Paper with designed speed of 550m/min and length of 4800mm. For the wet suction, SICER participate in the design, production and aftersale installtion to ensure the smooth start up. And the successfully operation project give more confidence in overseas’ overall project. Beside the Thuan an project in south of Vietnam, this project has more profoud significance in the north area of Vietnam.

Together we stand, the friendship betweet these two country will never diminish. Let’s follow the initiative of One Belt One Road and deepen the cooperation in the future.

Congrats on the biggest project for paper machine in AFRICA

Located in Nigeria, with speed of 1300m/min and trim width of over 6.6 meters, the project PM2 for DAHUA PAPER has been successfully come into service in June, 2022. Till now, there are two lines in DAHUA PAPER making package paper with total capacity of over 500,000 tons.

SICER supplied the full set of dewatering elements for this meaningful project.

Date back to the time when signed the contract, three years passed. We had worked hard on the drawing, engineering design, technical analysis with DAHUA PAPER. With more onlines meetings instead of assinging engineers on site, DAHUA finished the all the installation of Forming Board Boxes, Hydrofoil Boxes, Suction Boxes, Transfer Boxes and Felt Suction Boxes. After overall commisioning and levelling, trial running, the PM 2 has been successfully put into production.

This is our important step on Africa mainland. With this project included, SICER had equipped for paper mills with over 60 lines, which capacity are more than 1,500,000 tons. With good wear resisttance and corrosion resisttance for our 99 sub micron alumina( 99 Al2O3), we have cooperated with paper mills over the world, serving with best quality dewatering elements and top sales service.

SICER Representative Project of SiN material for Jiangxi Five Star Paper 5600/1100

Project introductuion:

Start up in 2021. Dec. 10th

Paper Machine: Voith

Design Speed: 1100m/min

GSM: 120-300

End Paper: Special Paper

Our customer, Jiangxi Five Star Paper mill, is located in Jiangxi Five Star paper mill is one of the subsidiarries of FIVE CONTENTS SPECIAL PAPER founded in 2014. Jiangxi Five Star is the biggest production base making special paper.

We supplied for their paper machine wire table with SiN dewatering elements for Low Vac, High Vac, Top Former, and Flet suction Boxes. SiN dewatering elements has better quality in wear resistance and roughness. It is well suitable for the high speed especially for over 1000m/min. With smaller roughness and improved dewatering ability, the energy costs have been dramaticlly decreased.

We devote to save maintenance costs for customer and provide the best aftersale services to improve the end paper performance.

Jiangsu Fantai Project of 5200/650 start up

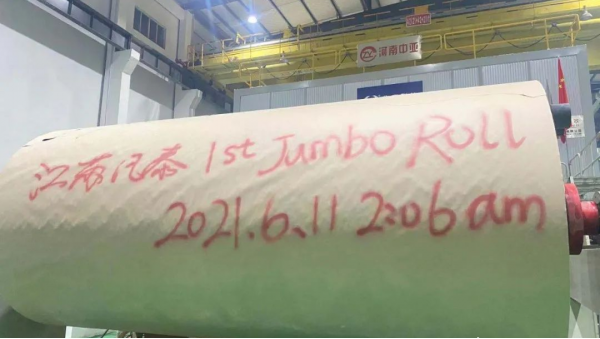

Jiangsu Fantai paper mill, founded in Dec, 2016, located in southeast of China Jiangsu Province, successfully wintness the first roll of paper after the investment on project of new paper machine.

Dated back to 2017, Fantai planned to invest a new production line for package paper. The paper machine had been confirmed to be provided by Henan Zhongya Intelligent Technology Co., Ltd. Which is well know company established in 1985. This paper machine is designed with trim width of 5200 and speed up to 650m/min, producing low gram high strenth corrugated paper out from full waste paper pulp. And its annual production capacity would achieve 200,000 tons.

Due to the pandemic infulence, this project has been delayed out of expectation. Thanks for the efforts of all the vendors and installation workers, the first roll of paper had successfully been produced in 11th, Jun, 2021. Thus, this paper machine became the biggest in this area with longest width, highest speed and maximum production capacity.

SICER, as the leading ceramic manufacturer in paper making industry, has supplied with full set of Alumina dewtering elements and stainless steel boxes. It contains forming board box, Hydrofoil box, Low vacuum box, and Duo high vacuum box and Tri high vacuum box. After installation and commission on site during the Dragon Boat Festival, the whole machine is well prepared and then be put in to service successfully. Congratulations on the successful project and we wish there will be more project prompting our contry’s paper making industry.

October 2019

Congratulations to the new project

On October 29, Hubei Shengda Paper 5200/600 dewatering components were successfully installated. The whole machine is equipped with Shandong Guiyuan ceramic components. So far, there are nearly 50nos paper machine projects supported by Shandong Guiyuan with capacity of more than 150,000 tons/year.

Thanks to all the customers who chose the SICER brand for their trust.SICER will continue to pursue excellence and innovation. The best gratitude is to protect the customer's production line with better products and better service.

January 2018

Congratulations to the new project

Congratulations!

A new project 5600/1000 paper machine run successfully! The arc top former was equipped with SICER ceramic dewatering elements.

Thanks for all the people who promote the high-speed paper machine dewatering elements localization. Thanks for your trust and support.

In face of strong beliefs, all difficulties will become insignificant.

July 2017

Guangxi 6600/1300 paper machine running smoothly for one year

Warmly congratulate Guangxi 6600/1300 paper machine smooth operation of dehydration components for one year. The return visit was informed that the service life of the forming network has been up to 10 months, and the paper quality and energy consumption are in full compliance with European standards.

Thanks to Valmet experts for guidance, help. Thanksgiving to friends who strengthen Valmet and SICER exchanges and cooperation.

June 2017

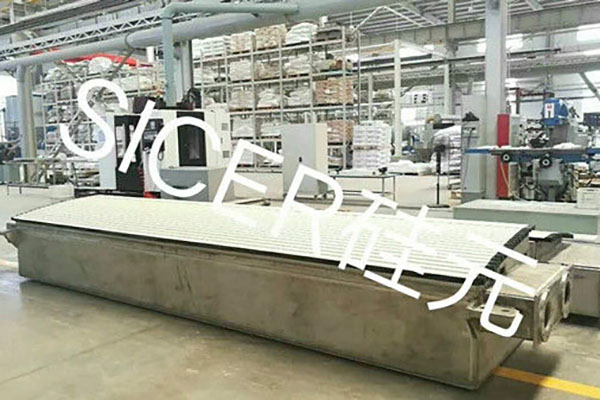

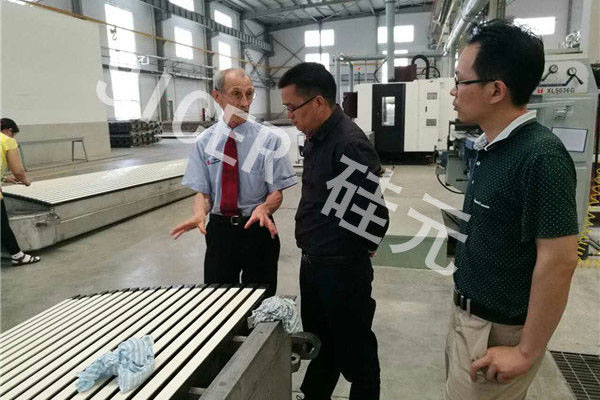

Large-scale forming machine project passed the customer inspection successfully

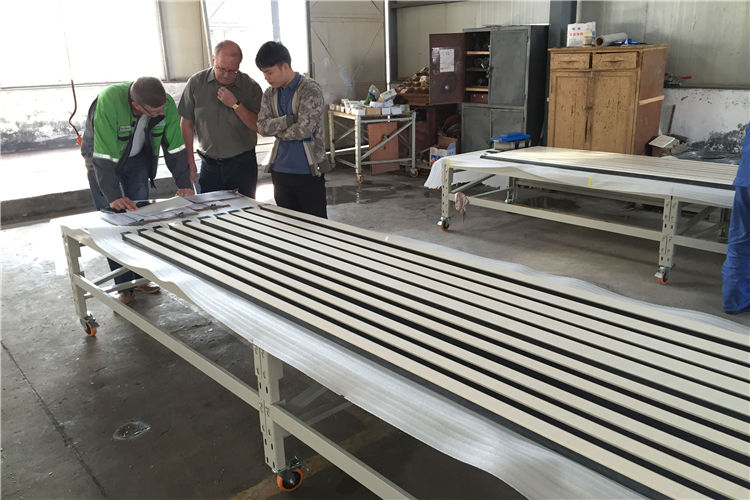

On June 3, 2017 Large forming machine box arrived. The weight of each box is nearly 10 tons. SICER provided the top ceramics.

On June 13, 2017, Mr. Liu Geng, from papermaking machinery factory and Mr. Frank Brown, the British customer, visited the new plant zone, and tested the box and the ceramic.

December 2016

Three wire 5800/700 high-speed paper machine project starting up

On December 29, 2016, India Triassic 5800/700 high-speed paper machine ceramic dewatering component, today began to enter the final installation stage.

This papermaking equipment is so far China's largest paper machine in India, the widest paper, the fastest running machine, which pour into the more advanced technology. On behalf of the domestic high-speed paper machine's highest manufacturing level, by Shandong Changhua paper Machinery and equipment company design and manufacturing.

Changhua company attaches great importance to the quality of top ceramic, in accordance with past practice, the import brand must be the best choice. This time choose SICER, which indicates that SICER brand has been deeply implanted in the hearts of customers, and product quality has been fully recognized by users. The history of the import brand monopoly high-speed paper machine dewatering components has end, there would be an alternative products appear.

This will be a milestone for SICER on the high-speed paper machine ceramic dewatering components to the world, and this is a good chance to expand the foreign market.

June 2016

Congratulations to Taizhou Forest 5200/900 three wire paper machine word smoothly

The 5200 paper machine project of dewatering components designed by Sicer for three layers of wire for Taizhou Forest Paper Co., Ltd. is an important milestone for our entering the field of high speed paper machine. The max working speed is up to 921 m/ min, and successfully break the foreign monopolyn of dewatering components in the field of Chinese high speed paper machine. As a result, its daily output exceeded 1000 tons, and the service life of forming wire up to 125 days, as much 38.9% costs saved than foreign brands of similar projects, achieved a rather remarkable saving effect. The alternative of the imported products also bring considerable economic and social benefits.

May 2016

Ceramic Dewatering elements used on 6600 wrapping paper machine successfully passed acceptance

January 5,2016,Ceramic dewatering elements (length is 7250mm, designing speed is 1300m/min) used on 6600 wrapping paper machine successfully passed acceptance and has been put into service. They have been made by Shandong Guiyuan Advanced Ceramics Co.,LTD.

These products are made of special ceramic materials and by advanced assembly, bonding, grinding processes, which have been developed by Sicer independently and been widely recognized in the market. The quality of the products conforms to the international standard.

The products put into production smoothly, that will lay a solid foundation for the internationalization of Sicer brand.Sicer warmly welcome new and old customers to visit the guidance and put forward valuable suggestions.