Factory best selling Ceramic Foam Filters For Casting - Hot sale China High Heat Resistance High Toughness Ceramic Dosing Metering Injection Filling Plunger Pump – Guiyuan

Short Description:

Product Detail

Product Tags

Related Video

Feedback (2)

Factory best selling Ceramic Foam Filters For Casting - Hot sale China High Heat Resistance High Toughness Ceramic Dosing Metering Injection Filling Plunger Pump – Guiyuan Detail:

We know that we only thrive if we can guarantee our combined price tag competiveness and top quality advantageous at the same time for Hot sale China High Heat Resistance High Toughness Ceramic Dosing Metering Injection Filling Plunger Pump, Our concept will be to help presenting the confidence of each buyers with all the offering of our most honest support, and the right products.

We know that we only thrive if we can guarantee our combined price tag competiveness and top quality advantageous at the same time for China Refractory Plunger Pump, High Hardress Dosing Pump, By continuous innovation, we will supply you with more valuable products and solutions and services, and also make a contribution for the development of the automobile industry at home and abroad. Both domestic and foreign merchants are strongly welcomed to join us to grow together.

Introduction

1. Sicer has rich ceramic material system, and can provide a variety of ceramic materials and self-lubricating properties materials;

2. Under the same working conditions, the service life of ceramic valve is more than 5-10 times that of ordinary metal valve;

3. Using the unique facing up technology of ceramic ball valve to make ceramic hard seal be reliable and stable;

4. Rich experience in valve ceramic material selection, can match the optimal selection scheme according to the working conditions (pressure, frequency, medium, etc.);

5. Electric/ pneumatic/ remote control on-off switch, optimum structural design and production precision to avoid abrupt breakdown and ensure the valve opening and closing freely and the stability of torque;

6. Sicer has developed a series of new ceramic valve products, such as ceramic C valve, ceramic slide valve and ceramic angle valve, and successfully promoted them to the market;

7. Widely used in various acid and alkali fluid, high temperature steam, mud, crude oil transportation and storage system. It is an ideal substitute for titanium metal valve and Monel valve under strong corrosion conditions. Tens of thousands of ceramic valves of various types have been applied.

8. Continuous technical consultation service before and after sales.

Application Cases

The world’s largest single coal-to-oil project

A new project of a domestic chemical enterprise

Basic Info

1. According to the working condition and some other particulare working condition of plunger pump, SICER would design special ceramic technique proposal and module choosing.

2. Both flexible and rigid seal can be probided for various requirement.

3. Paticular ceramic materials and self lubrication material can be supplied for matchaing of friction pair to reduce further abrasion.

4. Electric, pneumatic, and remote control can be done with smooth separating combing of valves.

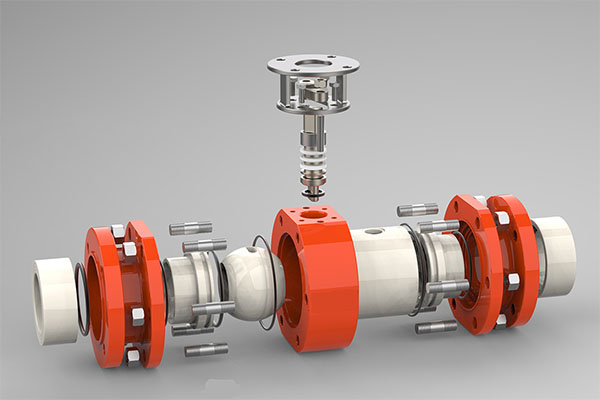

Products Show

Different Ceramic Materials for different related application.

1. Alumina (Al2O3) is one of the most economic ceramic materials, it has great corrosion and abrasion resistance properties.

2. Zirconium (ZrO2) is the highest strength and toughness at room temperature of all engineered ceramics. But this ZrO2 has operating temperature limitation, the Max temperature is 320 degC.

3. Silicon Nitride is one of great ceramic material especially used for high temperature application, special housing and ceramic parts permit solution temperature up to 950 degC.

4. Silicon Carbide is the most hardness material of all engineered ceramics, in the other word SiC hardness next to Diamond. But very low fracture toughness of SiC is a big weakness for ceramic parts, it’s easy be broken.

We know that we only thrive if we can guarantee our combined price tag competiveness and top quality advantageous at the same time for Hot sale China High Heat Resistance High Toughness Ceramic Dosing Metering Injection Filling Plunger Pump, Our concept will be to help presenting the confidence of each buyers with all the offering of our most honest support, and the right products.

Hot sale China Refractory Plunger Pump, High Hardress Dosing Pump, By continuous innovation, we will supply you with more valuable products and solutions and services, and also make a contribution for the development of the automobile industry at home and abroad. Both domestic and foreign merchants are strongly welcomed to join us to grow together.

Product detail pictures:

Related Product Guide:

We always continually offer you the most conscientious purchaser services, and the widest variety of designs and styles with finest materials. These efforts include the availability of customized designs with speed and dispatch for Factory best selling Ceramic Foam Filters For Casting - Hot sale China High Heat Resistance High Toughness Ceramic Dosing Metering Injection Filling Plunger Pump – Guiyuan, The product will supply to all over the world, such as: United States, Namibia, Swiss, With a wide range, good quality, reasonable prices and stylish designs, our products are extensively used in this field and other industries. We welcome new and old customers from all walks of life to contact us for future business relationships and achieving mutual success! We welcome customers, business associations and friends from all parts of the world to contact us and seek cooperation for mutual benefits.

We are a small company that has just started, but we get the company leader's attention and gave us a lot of help. Hope we can make progress together!