Short Lead Time for Ceramic Shaft Sleeve - OEM/ODM China China ACETRON 99.5% High Purity Al2O3 Ceramic Evaporation Crucible for PVD Coating – Guiyuan

Short Description:

Product Detail

Product Tags

Related Video

Feedback (2)

Short Lead Time for Ceramic Shaft Sleeve - OEM/ODM China China ACETRON 99.5% High Purity Al2O3 Ceramic Evaporation Crucible for PVD Coating – Guiyuan Detail:

The very abundant projects administration experiences and 1 to just one provider model make the higher importance of company communication and our easy understanding of your expectations for OEM/ODM China China ACETRON 99.5% High Purity Al2O3 Ceramic Evaporation Crucible for PVD Coating, Besides, our business sticks to good quality and realistic rate, and we also give fantastic OEM providers to quite a few famous brands.

The very abundant projects administration experiences and 1 to just one provider model make the higher importance of company communication and our easy understanding of your expectations for China pvd crusible, coating crusible, we always keep our credit and mutual benefit to our client, insist our high quality service to moving our clients. always welcome the our friends and clients to come and visit our company and guid our business, if you are interested in our products, you can also submit your purchase information online, and we will contact you immediately, we keep our highly sincere cooperation and wish everything in your side are all well.

Product Details

| Type | Refractory Material |

| Material | SiO2 |

| Working Temperature | ≤1650℃ |

| Shape | Square, Pipe, etc |

Product description

Quartz ceramic has excellent thermal shock resistance performance thanks to grain composition optimization. Quartz ceramic has a small coefficient of thermal expansion, good chemical stability and resistance to glass melt corrosion.

Alumina is a kind of ceramic material that have high thermal conductivity, high abrasion resisttance, compressive strength, high temperature resistance and and thermal shock resistacne. It’s also a suitalbe material for furnace use in crucible, which is low cost compared with other refractories.

There are two kinds of material for SICER Crucible, Alumina and Zirconia.

With excellent resistance to thermal shock, corrosion, and coefficient of thermal expansion, they are widely applied to the smelting process.

Alumina crucible has good acid and alkali resistance and is suitable for melting alloy and stainless steel. The maximum working temperature can reach 1600 ℃

Zirconia Crucible has excellent resistance to acid slag, and is widely used for smelting from the super alloy and the noble metal, and the optimal operating temperature is from 1980 to 2100℃.

Applications

Aluminum oxide crucible is widely used in the following application:

Used for making parts for CVD, ion implants, photolithography, and semiconductor parts.

Used for furnaces for metallurgy industry due to its ability serving under high temperature.

Used as protector for high temperature thermal couples.

Used for chemical industry with high corrosion resisttance.

Advantage

• Low thermal expansion

• Good thermal shock resistance

• Good chemical stability

• Low bulk density

• Resistance to glass melt corrosion

• Low porosity and fine surface enhance cleaness

• Superior mechanical strength and wear resisttance

• Excellent chemical resistance to acids and others

• Consistent dimensional control

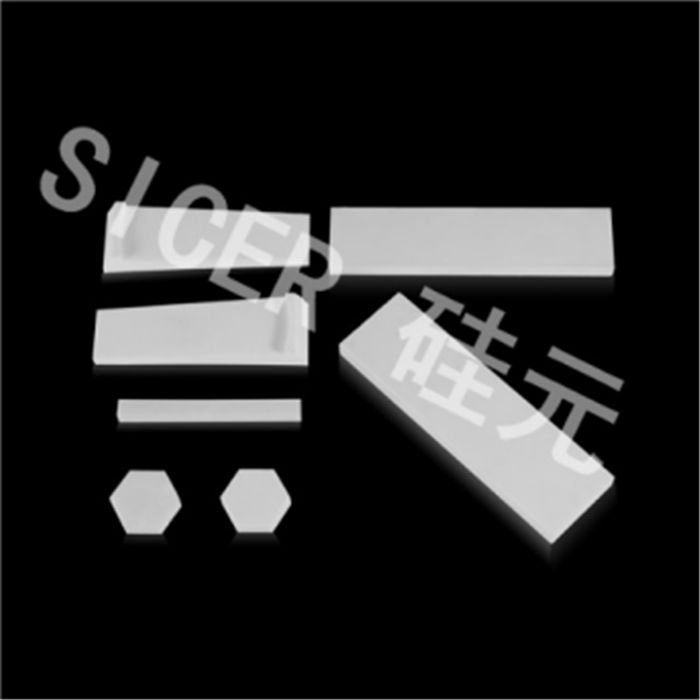

Products Show

The very abundant projects administration experiences and 1 to just one provider model make the higher importance of company communication and our easy understanding of your expectations for OEM/ODM China China ACETRON 99.5% High Purity Al2O3 Ceramic Evaporation Crucible for PVD Coating, Besides, our business sticks to good quality and realistic rate, and we also give fantastic OEM providers to quite a few famous brands.

OEM/ODM China China pvd crusible, coating crusible, we always keep our credit and mutual benefit to our client, insist our high quality service to moving our clients. always welcome the our friends and clients to come and visit our company and guid our business, if you are interested in our products, you can also submit your purchase information online, and we will contact you immediately, we keep our highly sincere cooperation and wish everything in your side are all well.

Product detail pictures:

Related Product Guide:

As for competitive charges, we believe that you will be searching far and wide for anything that can beat us. We will state with absolute certainty that for such excellent at such charges we have been the lowest around for Short Lead Time for Ceramic Shaft Sleeve - OEM/ODM China China ACETRON 99.5% High Purity Al2O3 Ceramic Evaporation Crucible for PVD Coating – Guiyuan, The product will supply to all over the world, such as: Auckland, Jeddah, Czech, Providing the best products, the most perfect service with the most reasonable prices are our principles. We also welcome OEM and ODM orders.Dedicated to strict quality control and thoughtful customer service, we are always available to discuss your requirements and ensure full customer satisfaction. We sincerely welcome friends to come negotiate business and start cooperation.

This enterprise in the industry is strong and competitive, advancing with the times and develop sustainable, we are very pleased to have a opportunity to cooperate!