Fixed Competitive Price Solid Ceramic Blade - Silicon Nitride Ceramic – Guiyuan

Short Description:

Product Detail

Product Tags

Related Video

Feedback (2)

Fixed Competitive Price Solid Ceramic Blade - Silicon Nitride Ceramic – Guiyuan Detail:

Basic Info

Production Name: Silicon Nitride Ceramic

Application: Aerospace, Nuclear, Petrochemical, Mechanical Engineering Industry

Material: Si3N4

Shape: Customized

Product description:

Silicon nitride ceramics have advantage over metal in many aspects. They are widely used in the fields of aerospace, nuclear, petrochemical, textile and mechanical engineering industries.

Advantage:

·Excellent mechanical property

·Low bulk density

·High strength and hardness

·Low friction coefficient

·Good lubricating function

·Resistance to metal corrosion

·Electric insulation

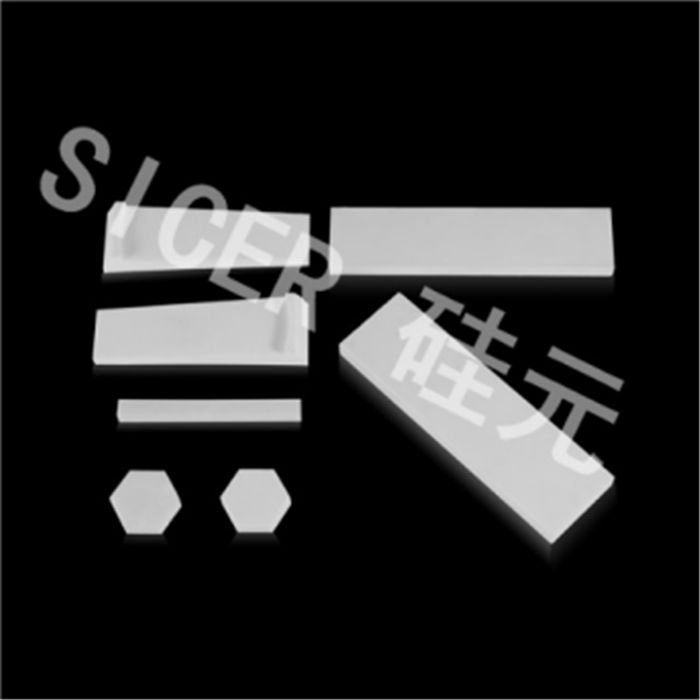

Products Show

Description:

Silicon nitride ceramics is superior to other materials due to its thermal shock resistance. It does not deteriorate at high temperatures, so it’s used for automotive engines and parts for gas turbines, including the turbocharger rotor.

Ortech offers a complete family of Silicon Nitride materials. These materials have the following key characteristics: No adhesive wear against steel, Twice as hard as tool steel, Good chemical resistance and 60% less weight than steel.

Silicon nitrides (Si3N4) are a range of advanced engineering ceramics characterised by high strength, toughness and hardness and excellent chemical and thermal stability.

Silicon nitride was discovered in the mid-nineteenth century but did not lend itself to ease of fabrication, due to its covalently bonded nature. This initially led to the development of two types of silicon nitride, reaction–bonded silicon nitride (RBSN) and hot pressed silicon nitride (HPSN). Subsequently, since the 1970s two further types have been developed: sintered silicon nitride (SSN), which include the sialons, and sintered reaction–bonded silicon nitride (SRBSN).

The current interest in silicon nitride based engineering materials essentially developed from the research in the 1980s into ceramic parts for gas turbine and piston engines. It was envisaged that an engine, predominately made from silicon nitride based parts, such as sialon, would be light weight and be able to operate at higher temperatures than traditional engines resulting in higher efficiencies. Ultimately however, this goal was not realised as a result of a number of factors including cost, the difficulty in reliably fabricating the parts and the inherent brittle nature of ceramics.

However, this work led to the development of a number of other industrial applications for silicon nitride based materials, such as in metal forming, industrial wear and molten metal handling.

The different types of silicon nitride, RBSN, HPSN, SRBSN and SSN, result from their method of fabrication, which governs their resulting properties and applications.

Product detail pictures:

Related Product Guide:

We insist on offering premium quality creation with very good company concept, honest product sales along with the finest and fast assistance. it will bring you not only the premium quality item and huge profit, but the most significant is to occupy the endless market for Fixed Competitive Price Solid Ceramic Blade - Silicon Nitride Ceramic – Guiyuan, The product will supply to all over the world, such as: Vietnam, Portugal, Kenya, Excellent quality comes from our adherence to every detail, and customer satisfaction comes from our sincere dedication. Relying on advanced technology and industry reputation of good cooperation, we try our best to provide more quality products and services to our customers, and all of us are willing to strengthen exchanges with domestic and foreign customers and sincere cooperation, to build a better future.

The factory can meet continuously developing economic and market needs, so that their products are widely recognized and trusted, and that's why we chose this company.