Isihlungi se-Ceramic Foam

Incazelo emfushane:

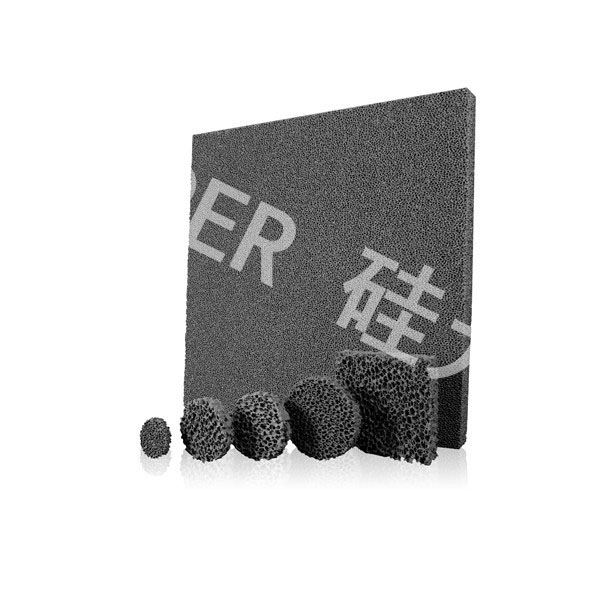

Njengomphakeli wekhwalithi ephezulu wesihlungi se-ceramic, i-SICER icaciswe ekwenziweni kwemikhiqizo ngezinhlobo ezine zezinto zokwakha, okuyi-silicon carbide(SICER-C), i-aluminium oxide(SICER-A), i-zirconium oxide(SICER-Z) ne-SICER-AZ. Isakhiwo sayo esiyingqayizivele senethiwekhi enezinhlangothi ezintathu singasusa ngempumelelo ukungcola kwensimbi encibilikisiwe, okungathuthukisa ukusebenza komkhiqizo kanye nesakhiwo esincane. Isihlungi se-ceramic se-SICER sisetshenziswe kabanzi embonini yokuhluza insimbi engenamvubelo kanye nokusakaza. Ngokuqondiswa kwesidingo semakethe, i-SICER ibilokhu igxile ku-R&D yemikhiqizo emisha.

Imininingwane Yomkhiqizo

Omaka bomkhiqizo

Njengomphakeli wekhwalithi ephezulu wesihlungi se-ceramic, i-SICER icaciswe ekwenziweni kwemikhiqizo ngezinhlobo ezine zezinto zokwakha, okuyi-silicon carbide(SICER-C), i-aluminium oxide(SICER-A), i-zirconium oxide(SICER-Z) ne-SICER-AZ. Isakhiwo sayo esiyingqayizivele senethiwekhi enezinhlangothi ezintathu singasusa ngempumelelo ukungcola kwensimbi encibilikisiwe, okungathuthukisa ukusebenza komkhiqizo kanye nesakhiwo esincane. Isihlungi se-ceramic se-SICER sisetshenziswe kabanzi embonini yokuhluza insimbi engenamvubelo kanye nokusakaza. Ngokuqondiswa kwesidingo semakethe, i-SICER ibilokhu igxile ku-R&D yemikhiqizo emisha.

Izihlungi ze-Ceramic Foam zisetshenziswa kakhulu ekuhlungeni i-aluminium, ithusi, insimbi, ama-alloys ensimbi kanye nokusakazwa kwensimbi. Isihlungi segwebu le-ceramic sinevolumu ephezulu kakhulu ye-porosity- ngaphezu kuka-90%, futhi indawo ephakeme kakhulu yokubamba okufakiwe. Ngokumelana okuhle kakhulu kokuhlasela kanye nokugqwala kwakha insimbi encibilikisiwe, izihlungi zingasusa ngokuphumelelayo izinto ezifakiwe, zinciphise igesi elivalelekile futhi zinikeze ukugeleza kwe-laminar, ukuze insimbi ehlungiwe ihlanzeke ngekhwalithi ephakeme, i-scrap encane, kanye namaphutha ambalwa, konke okufaka isandla ekusebenzeni okungcono. Yehlisa isiyaluyalu ngesikhathi sokulingisa futhi ivimbele izinto zangaphandle ukuthi zingene ekulingiseni.

Isihlungi se-Silicon Carbide

| Uhlobo | I-Refractory Material |

| Izinto zokwakha | I-SiC |

| I-Refractoriness (℃) | ≤1500 |

| Umbala | Okumpunga Okumnyama |

| I-Pore (ppi) | 10-60 |

| Usayizi | Ngokwezifiso |

| Isimo | Isikwele, Unxande, Umjikelezo njll. |

Isihlungi se-silicon carbide sikhiqizwa ngekhwalithi ephezulu ye-silicon carbide i-micro powder esekelwe kubuchule obuyingqayizivele bokubumba. Ilungele ukukhiqizwa kwe-iron castings ngaphansi kuka-1500 ℃ ngenxa yokuqina kwayo okuhle kakhulu kokushisa nokumelana nokushaqeka okuhle kokushisa.

Inzuzo

•Ukuzinza okuhle kakhulu kwe-thermal

•I-porosity ephezulu

•Ikhono elihle kakhulu lokumunca ukunciphisa ukufakwa

•Uhlu olubanzi lwezinketho zobukhulu kanye ne-pore diameter

•Ukumelana nokushaqeka okuhle kokushisa

•Ifanele ukukhiqizwa kwe-iron castings ngaphansi kwe-1500 ℃

Ukucaciswa Okubalulekile/Izici Ezikhethekile

| Ipharamitha yokusebenza | |||

| Compress Amandla(MPa) | I-Porosity(%) | Ukuminyana kwenqwaba(g/cm³) | I-Temp Esetshenziswayo℃ |

| ≥1.2 | 80-87 | ≤0.5 | ≤1500 |

| Amandla | |||

| Insimbi Empunga | 4Kg/cm2 | Insimbi ene-ductile | 1.5Kg/cm2 |

Bonisa Imikhiqizo

Isihlungi se-Aluminium oxide

| Uhlobo | I-Refractory Material |

| Izinto zokwakha | I-Al2O3 |

| I-Refractoriness (℃) | ≤1350 |

| Umbala | Emhlophe |

| I-Pore (ppi) | 10-60 |

| Usayizi | Ngokwezifiso |

| Isimo | Isikwele, Unxande, Umjikelezo njll. |

Isihlungi se-Aluminium oxide

Isihlungi se-aluminium oxide sisetshenziswa kakhulu ekuhlungeni i-aluminium, ingxubevange ye-aluminium nensimbi encibilikisiwe ngaphansi kuka-1350 ℃, singaxazulula izinkinga zangaphakathi nezinkinga zokuzwa ngaphakathi kwemikhiqizo ye-aluminium alloy futhi sinciphise izinga lokwenqaba.

Lonke uhla lwama-porosities kusuka ku-PPI 10 kuya ku-PPI 60 lunganikezwa.

Izihlungi kubo bonke osayizi bama-commen: 7x7x2'', 9x9x2'', 12x12x2''. 15x15x2'', 17x17x2'', 20x20x2'', 23x23x2''.

Inzuzo

•Inqubo yokukhiqiza eco-friendly

•Amandla aphezulu aphezulu

•Uhlu olubanzi lwezinketho zobukhulu kanye ne-pore diameter

•Ukusebenza okungcono kokugeleza

•Khipha ngempumelelo ukufakwa futhi wehlise izinga lokwenqaba

•Imiphetho egobile kanye ne-gasket ecindezelayo

Ukucaciswa Okubalulekile/Izici Ezikhethekile

| Ipharamitha yokusebenza | ||||

| Uhlobo | Compress Amandla(MPa) | I-Porosity(%) | Ukuminyana kwenqwaba(g/cm³) | I-Temp Esetshenziswayo℃ |

| U-SICER-A | ≥0.8 | 80-90 | 0.4~0.5 | 1260 |

| Ukucaciswa kanye Nomthamo | ||||

| Usayizi mm(intshi) | Ukugeleza(kg/min) | Amandla(≤t) | ||

| 432*432*50(17') | 180-370 | 35 | ||

| 508*508*50(20') | 270~520 | 44 | ||

| 584*584*50(23') | 360-700 | 58 | ||

Bonisa Imikhiqizo

Isihlungi se-Zirconia oxide

| Uhlobo | I-Refractory Material |

| Izinto zokwakha | ZrO2 |

| I-Refractoriness (℃) | ≤1750 |

| Umbala | Okuphuzi |

| I-Pore (ppi) | 10-60 |

| Usayizi | Ngokwezifiso |

| Isimo | Isikwele, Unxande, Umjikelezo njll. |

Incazelo yomkhiqizo

Isihlungi se-Zirconium oxide sikhiqizwa kusuka ku-ziconia ehlanzekile ngokususelwa kundlela yokukhiqiza ethuthukisiwe. Ihloselwe ukusetshenziswa ekuhlungeni insimbi engagqwali, i-carbon steel nokunye ukuncibilika kwengxubevange eshisayo ngaphansi kwe-1750 ℃, kungathuthukisa izinga lomkhiqizo ofanelekile wokulingisa futhi kunciphise ukuguga kwesikhunta.

Inzuzo

•Ukuhlanzeka okuphezulu kwe-zironia njengento eluhlaza

•Indlela yokukhiqiza esezingeni eliphezulu

•Uhlu olubanzi lwezinketho zobukhulu kanye ne-pore diameter

•Impahla yemishini enhle kakhulu futhi ayikho i-slag

•Ukumelana nokushaqeka okuphezulu okushisayo

•Yehlisa ngempumelelo i-reoxidation kanye nesici esingaphansi komhlaba

•Sefa ngokuphumelelayo izinhlayiya ezingezona ezensimbi, i-slag

•Yehlisa ukuguga kwesikhunta futhi wenze lula uhlelo lokungena

Ukucaciswa Okubalulekile/Izici Ezikhethekile

| Ipharamitha yokusebenza | ||||

| Uhlobo | Compress Amandla(MPa) | I-Porosity(%) | Ukuminyana kwenqwaba(g/cm³) | I-Temp Esetshenziswayo℃ |

| I-SICER-Z | ≥2.5 | 77-83 | ≤1.2 | ≤1750 |

| Amandla | ||||

| Insimbi ye-carbon | 1.5-2.5Kg/cm2 | Insimbi engagqwali | 2.0-3.5Kg/cm2 | |

Bonisa Imikhiqizo