Ama-Deawtering Elements

Incazelo emfushane:

Uma kuqhathaniswa nezinto zokususa amanzi epulasitiki, izembozo ze-ceramic zilungele lonke uhla lwejubane lomshini wephepha. Ngenxa yokusebenza kwayo okukhethekile, izembozo ze-ceramic zinesikhathi eside sokuphila. Ngohlelo oluhlukile lwenhlanganisela kanye nesakhiwo esenziwe sathuthukiswa, ikhava yethu yobumba iye yafakazelwa iyindlela engcono yokukhipha amanzi, ukwakheka, ukucwengisiswa, ukushelela ngemva kokufaka isicelo.

Imininingwane Yomkhiqizo

Omaka bomkhiqizo

Imininingwane Yomkhiqizo

Uma kuqhathaniswa nezinto zokususa amanzi epulasitiki, izembozo ze-ceramic zilungele lonke uhla lwejubane lomshini wephepha. Ngenxa yokusebenza kwayo okukhethekile, izembozo ze-ceramic zinesikhathi eside sokuphila. Ngohlelo oluhlukile lwenhlanganisela kanye nesakhiwo esenziwe sathuthukiswa, ikhava yethu yobumba iye yafakazelwa iyindlela engcono yokukhipha amanzi, ukwakheka, ukucwengisiswa, ukushelela ngemva kokufaka isicelo.

Incazelo Yomkhiqizo

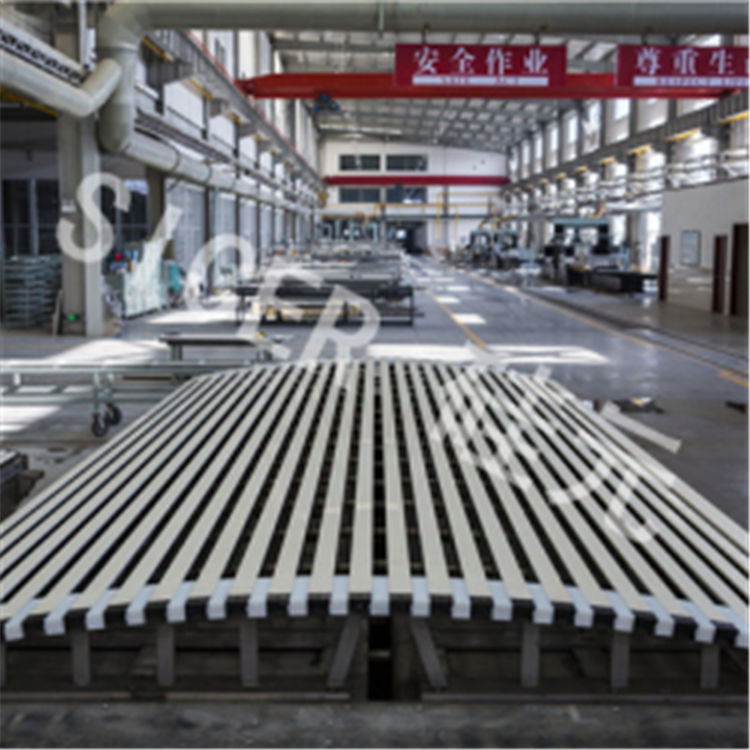

Ukuphela okumanzi komshini we-fourdrinier kungenye yezinto ezinqumayo zokusebenza kanye nekhwalithi yephepha lokugcina. Lapho ishidi lephepha libanjwe ohlangothini olungaphezulu lwendwangu, i-fiber iyahlangana futhi ihlanganiswe ndawonye. Kuleli qophelo, indawo ebonakalayo yeshidi yenziwe.

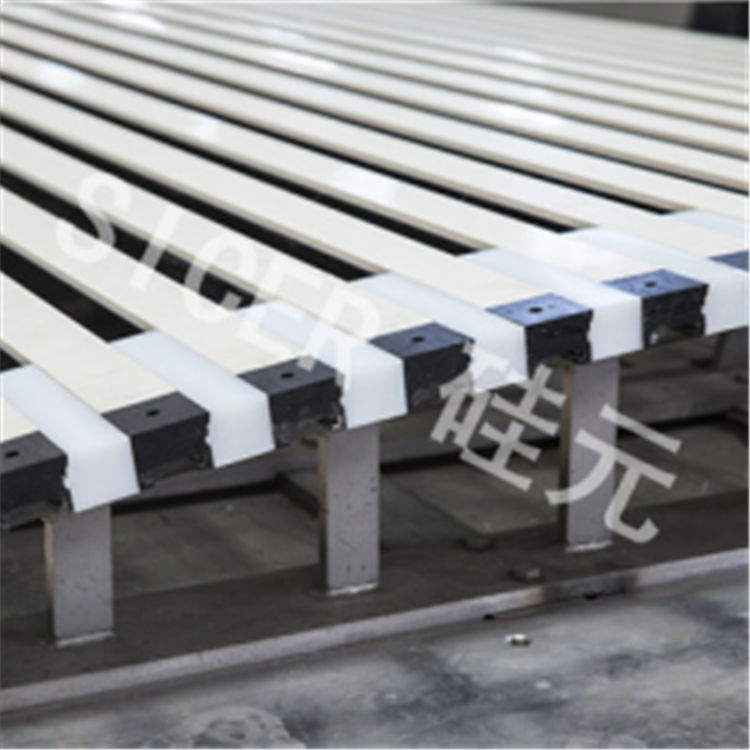

Uma kuqhathaniswa nezinto zepulasitiki ze-HDPE, iphaneli ye-ceramic drainage inokusebenza okungcono kwamandla, ukumelana nokushaqeka okushisayo, ukuzinza, ukuqina, ukumelana nokugqokwa, nokukhathala futhi akulula ukuguga. Ngemva kokushintsha amakhava e-ceramic, ubuqotho betafula lezintambo, ukucaba kanye nokuqina kuyathuthuka.

inkampani yethu ithuthukisa ngokuphindaphindiwe ikhwalithi yemikhiqizo yethu ukuze ihlangabezane nezifiso zomshini wephepha wejubane eliphezulu futhi igxile nakakhulu ekuphepheni, ukwethembeka, izidingo zemvelo, kanye nokusungulwa kwe-Dewatering Element ye-Paper Mill, sidlala indima ehamba phambili ekuhlinzekeni amaklayenti ngezinto eziphezulu.

Ngokumelana okuhle kokugqoka kanye ne-coefficient ephansi yenganekwane, imikhiqizo yethu iyakwazi ukwelula impilo yendwangu kuze kufike ezinsukwini eziyi-125. Izindleko zilondolozwe ngendlela emangalisayo.

Besilokhu sinamathela kufilosofi "yokuheha amakhasimende ngezinto ezihamba phambili kanye nenkonzo enhle kakhulu". Singahlinzeka ngemiklamo yobunjiniyela ngokuya ngohlobo lomshini wephepha ohlukahlukene kanye nebanga lephepha ukuze siqinisekise imiphumela emihle yokuphelelwa amanzi emzimbeni. Samukela amakhasimende, izinhlangano zamabhizinisi nabangane abavela kuzo zonke izingxenye zomhlaba ukuze baxhumane nathi futhi bafune ukubambisana ukuze bathole izinzuzo ezifanayo.

Inzuzo Eyinhloko Yokuncintisana

•I-coefficient yokungqubuzana okuphansi

•Isakhiwo esizinzile

•I-matrix yamandla aphezulu ye-fiber glass/carbon fiber

•Kulula ukufaka esikhundleni

•Izinga lokunamathela eliphansi lezingxube

•Ibha enyakazayo

•Vikela ngempumelelo intambo eyakhayo

•Impilo ende yesevisi

Imininingwane Esheshayo

| Okubalulekile | Ukuminyana kwenqwaba | Gobisa amandla | Ukuqina | Ukuqina | Ukumelana nokushaqeka okushisayo | Ukushisa kwe-conductivity |

| (g/cm3) | (Mpa) | (UMpa.M2/1) | (Kg/mm2) | (10o/C) | (W/mk) | |

| U-Sicer-A | 3.81-3.84 | 360-400 | 4.0-5.0 | 1350-1450 | 7.0-8.0 | 18-20 |

| I-Sicer-SubA | 3.86-3.88 | 380-420 | 5.0-6.0 | 1450-1530 | 7.0-8.0 | 20-25 |

| Sicer-AZ | 5.65-5.75 | 900-1100 | 5.0-6.0 | 1400-1500 | 9.0-10.0 | 3-4 |

| I-Sicer-ZROX | 5.70-5.75 | 900-1100 | 8.0-9.0 | 1200-1250 | 9.0-10.0 | 1-2 |

| I-Sicer-ASC | 3.05-3.10 | 350-400 | 4.0-4.5 | 2000-2400 | 4.0-4.5 | 80--90 |

| I-Sicer-SN | 3.05-3.20 | 650-750 | 6.0-6.7 | 1650-1750 | 2.5-3.0 | 30--50 |

I-Dewatering Elements- AlOx

Ikhwalithi ephezulu ye-aluminium oxide ku-submiron 99% ingasetshenziswa ezinhlobonhlobo zejubane lomshini ngempumelelo yezindleko ezingcono kakhulu.

Ubukhulu. Ubude ~ 9000mm

Ukumelana okuhle kokugqoka

Ubulukhuni obuphansi

Uhlelo lokusebenza olubanzi

Ukunakekelwa okuphansi

Kuqiza kahle

Aokufakelwe: i-talbe yocingo egcwele ngaphansi kuka-800m/min

Ibhokisi lokudonsa amanzi ngaphansi kuka-1200m/min

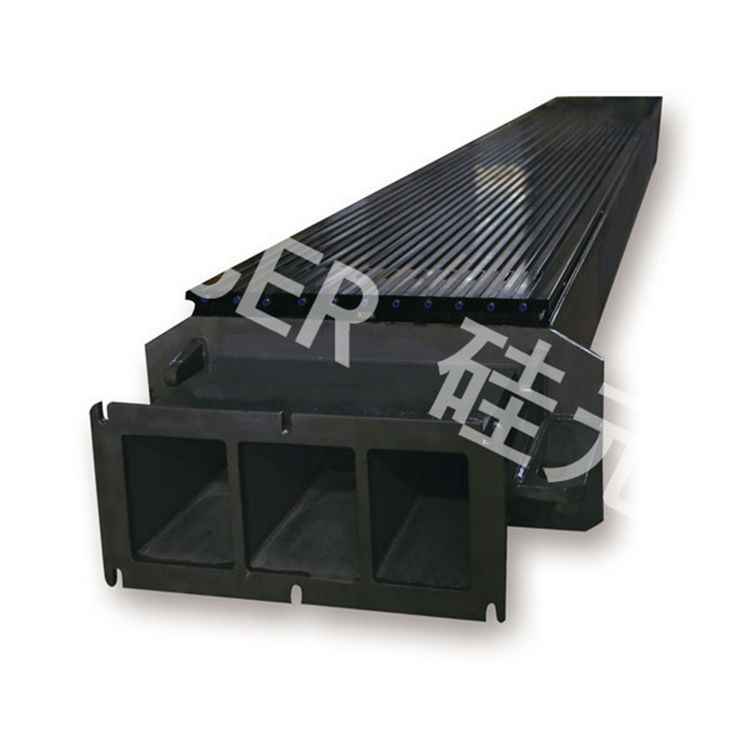

I-Dewatering Elements-SN

Izakhi zokuqeda amanzi ze-SICER-SN zisebenzisa izinto eziqinile njengesisekelo, ezimbozwe ngezinsimbi zekhwalithi ephezulu ze-SiN engagugi. Ukunemba kwayo okuphelele kanye nekhwalithi enhle yemishini yaqinisekisa ukufakwa okuphephile nokushintshwa. Ngokuhlanganisa okungenamthungo, awukho ukhiye wepiyano ovele kukhava.

Izinto ezisezingeni eliphakeme ze-Si3N4

Ukusebenza okuthembekile kwesikhathi eside

Ukumelana nokugqoka okuphezulu

Ukukhipha amanzi okungaguquki

Kufakelwe isicelo: ikhava yevacuum noma ingxenye yokucindezela ngaphansi kuka-1500m/min

I-Dewatering Elements- ZA

I-Dewatering Elements-ZROx

Ukuvikelwa okungcono kwemizwa futhi kunwebe impilo yayo

I-coefficient ephansi yokungqubuzana

Ubushelelezi kanye nekhwalithi yendawo ethuthukisiwe

Isetshenziselwa: isigaba sokucindezela ngaphansi kwesivinini somshini esingu-1000m/min

I-Dewatering Elements-AZ

Okuqukethwe kokubalulekile: Al2O3 kanye ne-ZirO2

Ukusebenza okuthembekile kwesikhathi eside

Ukumelana nokugqoka okuphezulu

I-Drainage ephumelelayo

Ukusetshenziswa kwamandla okuphansi

Kufakelwe isicelo: ikhava yevacuum noma ingxenye yokucindezela ngaphansi kuka-1500m/min