I-China Silicon Carbide Ceramic Foam Filter Ethengiswa Kakhulu ye-Foundry & Metallurgy

Incazelo emfushane:

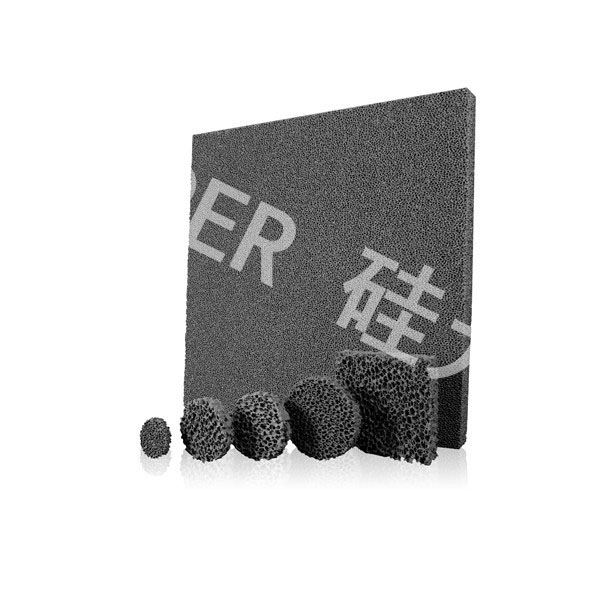

Njengomphakeli wekhwalithi ephezulu wesihlungi se-ceramic, i-SICER icaciswe ekwenziweni kwemikhiqizo ngezinhlobo ezine zezinto zokwakha, okuyi-silicon carbide(SICER-C), i-aluminium oxide(SICER-A), i-zirconium oxide(SICER-Z) ne-SICER-AZ. Isakhiwo sayo esiyingqayizivele senethiwekhi enezinhlangothi ezintathu singasusa ngempumelelo ukungcola kwensimbi encibilikisiwe, okungathuthukisa ukusebenza komkhiqizo kanye nesakhiwo esincane. Isihlungi se-ceramic se-SICER sisetshenziswe kabanzi embonini yokuhluza insimbi engenamvubelo kanye nokusakaza. Ngokuqondiswa kwesidingo semakethe, i-SICER ibilokhu igxile ku-R&D yemikhiqizo emisha.

Imininingwane Yomkhiqizo

Omaka bomkhiqizo

Inhlangano igcina umqondo wenqubo othi "ukuphathwa kwesayensi, ikhwalithi yephrimiyamu kanye nokubaluleka kokusebenza ngempumelelo, umthengi ophakeme Wesihlungi Sase-China Silicon Carbide Ceramic Foam Esithengiswa Kakhulu Se-Foundry & Metallurgy, Samukela amathemba amasha naphelelwe yisikhathi avela kuzo zonke izigaba zokuphila ukuze axhumane nathi ukuze uthole ukusebenzelana kwebhizinisi elincane okulindelwe esikhathini esizayo kanye nokuzuza okufanayo!

Inhlangano igcina emcabangweni wenqubo othi “ukuphathwa kwesayensi, ikhwalithi ye-premium kanye nokubaluleka kokusebenza ngempumelelo, umthengi ophakemeIsihlungi se-Ceramic Foam sase-China, Isitini esiphikisayo, Sesineminyaka engaphezu kwengu-10 sisebenza. Sizinikele emikhiqizweni yekhwalithi kanye nokwesekwa kwabathengi. Njengamanje singabanikazi bemikhiqizo engama-27 kanye namalungelo obunikazi okuklama. Sikumema ukuthi uvakashele inkampani yethu ukuze uthole ukuvakasha komuntu siqu kanye nesiqondiso sebhizinisi esithuthukisiwe.

Njengomphakeli wekhwalithi ephezulu wesihlungi se-ceramic, i-SICER icaciswe ekwenziweni kwemikhiqizo ngezinhlobo ezine zezinto zokwakha, okuyi-silicon carbide(SICER-C), i-aluminium oxide(SICER-A), i-zirconium oxide(SICER-Z) ne-SICER-AZ. Isakhiwo sayo esiyingqayizivele senethiwekhi enezinhlangothi ezintathu singasusa ngempumelelo ukungcola kwensimbi encibilikisiwe, okungathuthukisa ukusebenza komkhiqizo kanye nesakhiwo esincane. Isihlungi se-ceramic se-SICER sisetshenziswe kabanzi embonini yokuhluza insimbi engenamvubelo kanye nokusakaza. Ngokuqondiswa kwesidingo semakethe, i-SICER ibilokhu igxile ku-R&D yemikhiqizo emisha.

Izihlungi ze-Ceramic Foam zisetshenziswa kakhulu ekuhlungeni i-aluminium, ithusi, insimbi, ama-alloys ensimbi kanye nokusakazwa kwensimbi. Isihlungi segwebu le-ceramic sinevolumu ephezulu kakhulu ye-porosity- ngaphezu kuka-90%, futhi indawo ephakeme kakhulu yokubamba okufakiwe. Ngokumelana okuhle kakhulu kokuhlasela kanye nokugqwala kwakha insimbi encibilikisiwe, izihlungi zingasusa ngokuphumelelayo izinto ezifakiwe, zinciphise igesi elivalelekile futhi zinikeze ukugeleza kwe-laminar, ukuze insimbi ehlungiwe ihlanzeke ngekhwalithi ephakeme, i-scrap encane, kanye namaphutha ambalwa, konke okufaka isandla ekusebenzeni okungcono. Yehlisa isiyaluyalu ngesikhathi sokulingisa futhi ivimbele izinto zangaphandle ukuthi zingene ekulingiseni.

Isihlungi se-Silicon Carbide

| Uhlobo | I-Refractory Material |

| Izinto zokwakha | I-SiC |

| I-Refractoriness (℃) | ≤1500 |

| Umbala | Okumpunga Okumnyama |

| I-Pore (ppi) | 10-60 |

| Usayizi | Ngokwezifiso |

| Isimo | Isikwele, Unxande, Umjikelezo njll. |

Isihlungi se-silicon carbide sikhiqizwa ngekhwalithi ephezulu ye-silicon carbide i-micro powder esekelwe kubuchule obuyingqayizivele bokubumba. Ilungele ukukhiqizwa kwe-iron castings ngaphansi kuka-1500 ℃ ngenxa yokuqina kwayo okuhle kakhulu kokushisa nokumelana nokushaqeka okuhle kokushisa.

Inzuzo

•Ukuzinza okuhle kakhulu kwe-thermal

•I-porosity ephezulu

•Ikhono elihle kakhulu lokumunca ukunciphisa ukufakwa

•Uhlu olubanzi lwezinketho zobukhulu kanye ne-pore diameter

•Ukumelana nokushaqeka okuhle kokushisa

•Ifanele ukukhiqizwa kwe-iron castings ngaphansi kwe-1500 ℃

Ukucaciswa Okubalulekile/Izici Ezikhethekile

| Ipharamitha yokusebenza | |||

| I-Compress Strength (MPa) | I-Porosity (%) | Ukuminyana ngobuningi (g/cm³) | ITemp Esetshenziswayo ℃ |

| ≥1.2 | 80-87 | ≤0.5 | ≤1500 |

| Amandla | |||

| Insimbi Empunga | 4Kg/cm2 | Insimbi ene-ductile | 1.5Kg/cm2 |

Bonisa Imikhiqizo

Isihlungi se-Aluminium oxide

| Uhlobo | I-Refractory Material |

| Izinto zokwakha | I-Al2O3 |

| I-Refractoriness (℃) | ≤1350 |

| Umbala | Emhlophe |

| I-Pore (ppi) | 10-60 |

| Usayizi | Ngokwezifiso |

| Isimo | Isikwele, Unxande, Umjikelezo njll. |

Isihlungi se-Aluminium oxide

Isihlungi se-aluminium oxide sisetshenziswa kakhulu ekuhlungeni i-aluminium, ingxubevange ye-aluminium nensimbi encibilikisiwe ngaphansi kuka-1350 ℃, singaxazulula izinkinga zangaphakathi nezinkinga zokuzwa ngaphakathi kwemikhiqizo ye-aluminium alloy futhi sinciphise izinga lokwenqaba.

Lonke uhla lwama-porosities kusuka ku-PPI 10 kuya ku-PPI 60 lunganikezwa.

Izihlungi kubo bonke osayizi bama-commen: 7x7x2'', 9x9x2'', 12x12x2''. 15x15x2'', 17x17x2'', 20x20x2'', 23x23x2''.

Inzuzo

•Indlela yokukhiqiza eco-friendly

•Amandla aphezulu aphezulu

•Uhlu olubanzi lwezinketho zobukhulu kanye ne-pore diameter

•Ukusebenza okungcono kokugeleza

•Khipha ngempumelelo ukufakwa futhi wehlise izinga lokwenqaba

•Imiphetho egobile kanye ne-gasket ecindezelayo

Ukucaciswa Okubalulekile/Izici Ezikhethekile

| Ipharamitha yokusebenza | ||||

| Uhlobo | I-Compress Strength (MPa) | I-Porosity (%) | Ukuminyana ngobuningi (g/cm³) | ITemp Esetshenziswayo ℃ |

| U-SICER-A | ≥0.8 | 80-90 | 0.4~0.5 | 1260 |

| Ukucaciswa kanye Nomthamo | ||||

| Usayizi mm(intshi) | Ukugeleza (kg/min) | Amandla (≤t) | ||

| 432*432*50(17') | 180-370 | 35 | ||

| 508*508*50(20') | 270~520 | 44 | ||

| 584*584*50(23') | 360-700 | 58 | ||

Bonisa Imikhiqizo

Isihlungi se-Zirconia oxide

| Uhlobo | I-Refractory Material |

| Izinto zokwakha | ZrO2 |

| I-Refractoriness (℃) | ≤1750 |

| Umbala | Okuphuzi |

| I-Pore (ppi) | 10-60 |

| Usayizi | Ngokwezifiso |

| Isimo | Isikwele, Unxande, Umjikelezo njll. |

Incazelo yomkhiqizo

Isihlungi se-Zirconium oxide sikhiqizwa kusuka ku-ziconia ehlanzekile ngokusekelwe kumasu okukhiqiza athuthukile. Ihloselwe ukusetshenziswa ekuhlungeni insimbi engagqwali, i-carbon steel nokunye ukuncibilika kwe-alloy eshisayo ngaphansi kwe-1750 ℃, ingathuthukisa izinga lomkhiqizo ofanelekile wokulingisa futhi inciphise ukuguga kwesikhunta.

Inzuzo

•Ukuhlanzeka okuphezulu kwe-zironia njengento eluhlaza

•Indlela yokukhiqiza esezingeni eliphezulu

•Uhlu olubanzi lwezinketho zobukhulu kanye ne-pore diameter

•Impahla yemishini enhle kakhulu futhi ayikho i-slag

•Ukumelana nokushaqeka okuphezulu okushisayo

•Yehlisa ngempumelelo i-reoxidation kanye nesici esingaphansi komhlaba

•Sefa ngokuphumelelayo izinhlayiya ezingezona ezensimbi, i-slag

•Yehlisa ukuguga kwesikhunta futhi wenze lula uhlelo lokungena

Ukucaciswa Okubalulekile/Izici Ezikhethekile

| Ipharamitha yokusebenza | ||||

| Uhlobo | I-Compress Strength (MPa) | I-Porosity (%) | Ukuminyana ngobuningi (g/cm³) | ITemp Esetshenziswayo ℃ |

| I-SICER-Z | ≥2.5 | 77-83 | ≤1.2 | ≤1750 |

| Amandla | ||||

| Insimbi ye-carbon | 1.5-2.5Kg/cm2 | Insimbi engagqwali | 2.0-3.5Kg/cm2 | |

Bonisa Imikhiqizo

Inhlangano igcina umqondo wenqubo othi "ukuphathwa kwesayensi, ikhwalithi yephrimiyamu kanye nokubaluleka kokusebenza ngempumelelo, umthengi ophakeme Wesihlungi Sase-China Silicon Carbide Ceramic Foam Esithengiswa Kakhulu Se-Foundry & Metallurgy, Samukela amathemba amasha naphelelwe yisikhathi avela kuzo zonke izigaba zokuphila ukuze axhumane nathi ukuze uthole ukusebenzelana kwebhizinisi elincane okulindelwe esikhathini esizayo kanye nokuzuza okufanayo!

Ithengisa KakhuluIsihlungi se-Ceramic Foam sase-China, Isitini esiphikisayo, Sesineminyaka engaphezu kwengu-10 sisebenza. Sizinikele emikhiqizweni yekhwalithi kanye nokwesekwa kwabathengi. Njengamanje singabanikazi bemikhiqizo engama-27 kanye namalungelo obunikazi okuklama. Sikumema ukuthi uvakashele inkampani yethu ukuze uthole ukuvakasha komuntu siqu kanye nesiqondiso sebhizinisi esithuthukisiwe.