Lintho tsa Deawtering

Tlhaloso e Khutšoanyane:

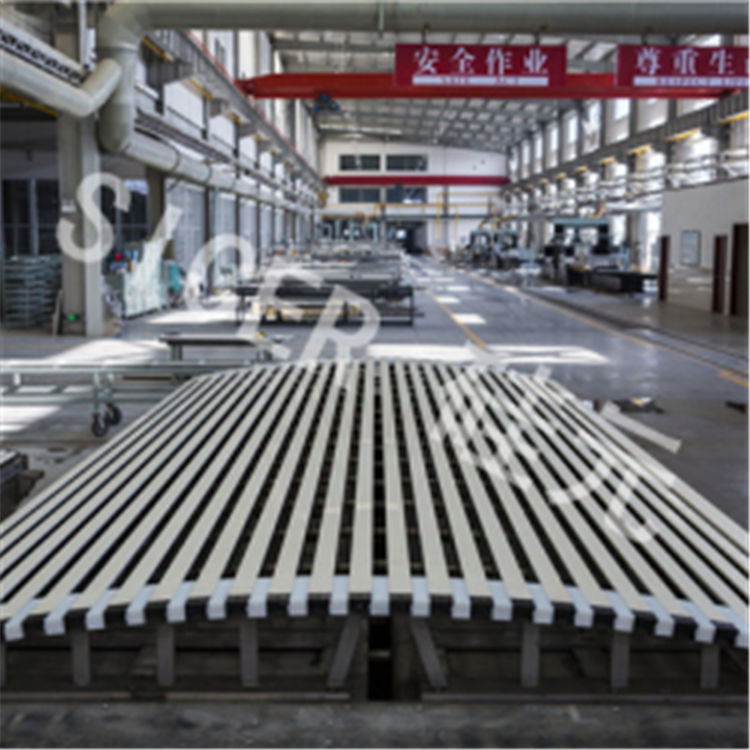

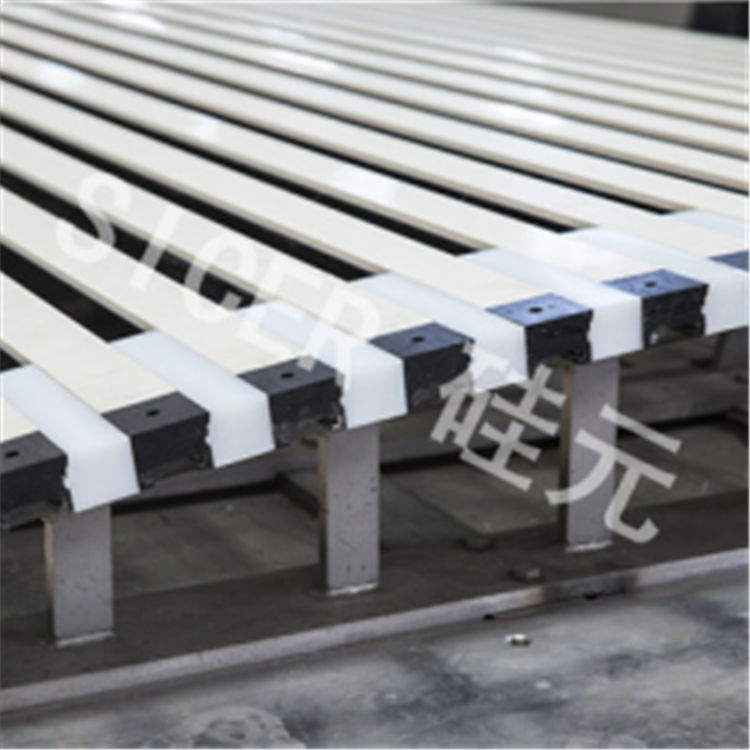

Ha ho bapisoa le lisebelisoa tsa polasetiki, likoahelo tsa ceramic li loketse mefuta eohle ea lebelo la mochini oa pampiri. Ka lebaka la ts'ebetso ea eona e ikhethang, sekoaelo sa ceramic se na le nako e telele ea bophelo. Ka sistimi e ikhethang ea composit le sebopeho se ntlafalitsoeng, sekoaelo sa rona sa ceramic se ipakile e le drainage e ntle, sebopeho, hloekiso, boreleli kamora kopo.

Lintlha tsa Sehlahisoa

Li-tag tsa Sehlahisoa

Lintlha tsa Sehlahisoa

Ha ho bapisoa le lisebelisoa tsa polasetiki, likoahelo tsa ceramic li loketse mefuta eohle ea lebelo la mochini oa pampiri. Ka lebaka la ts'ebetso ea eona e ikhethang, sekoaelo sa ceramic se na le nako e telele ea bophelo. Ka sistimi e ikhethang ea composit le sebopeho se ntlafalitsoeng, sekoaelo sa rona sa ceramic se ipakile e le drainage e ntle, sebopeho, hloekiso, boreleli kamora kopo.

Tlhaloso ea Sehlahisoa

Qetello e metsi ea mochine oa fourdrinier ke e 'ngoe ea lintlha tse khethollang ts'ebetso le boleng ba pampiri ea ho qetela. Hang ha pampiri ea pampiri e ts'oaroe ka lehlakoreng le ka holimo la lesela, fiber e kopana 'me e tlama hammoho. Hona joale ntlheng ena, thepa ea tlhaho ea lakane e entsoe.

Ha ho bapisoa le thepa ea polasetiki ea HDPE, phanele ea drainage ea ceramic e na le ts'ebetso e betere ka matla, ho hanyetsa mocheso oa mocheso, botsitso, ho tiea, ho hanyetsa, le mokhathala le ha ho bonolo ho fetoha. Kamora ho fetoha likoahelo tsa ceramic, tafole ea terata 'ho otloloha, ho bata le ho hlaka hoa ntlafala.

khamphani ea rona ka makhetlo a mangata e ntlafatsa boleng ba lihlahisoa tsa rona ho finyella litakatso tsa mochine o phahameng oa pampiri le ho tsepamisa maikutlo ho ts'ireletseho, botšepehi, litlhoko tsa tikoloho, le boqapi ba Dewatering Element bakeng sa Pampiri ea Pampiri, re phetha karolo e ka sehloohong ea ho fana ka bareki ka lintho tsa boleng bo phahameng.

Ka khanyetso e ntle ea ho apara le coefficient e tlase ea tšōmo, lihlahisoa tsa rona li khona ho lelefatsa bophelo ba lesela ho fihlela matsatsi a 125. Litšenyehelo kaofela li bolokiloe haholo.

Re ntse re khomarela filosofi ea "ho hohela bareki ka lintho tse ntle ka ho fetisisa le tšebeletso e babatsehang". Re ka fana ka meralo ea boenjiniere ho latela mefuta e fapaneng ea mochini oa pampiri le boemo ba pampiri ho netefatsa litlamorao tse ntle tsa dehydration. Re amohela bareki, mekhatlo ea likhoebo le metsoalle ho tsoa likarolong tsohle tsa lefats'e ho ikopanya le rona le ho batla tšebelisano-'moho molemong oa bobeli.

Molemo oa Pele oa Tlholisano

•Coefficient e tlase ea likhohlano

•Sebopeho se tsitsitseng

•Matrix a matla a phahameng a fiber glass/carbon fiber

•Ho bonolo ho nkela sebaka

•Sekhahla se tlase sa sekhomaretsi bakeng sa metsoako

•Sebaka se tsamaeang

•Sireletsa ka katleho ho etsa terata

•Bophelo bo bolelele ba tšebeletso

Lintlha tse Potlakileng

| Lintho tse bonahalang | Boima ba Bongata | Matla a kobehang | Mathata | Ho thatafala | Ho hanyetsa mocheso oa mocheso | Conductivity ea mocheso |

| (g/cm3) | (Mpa) | (Mpa.M2/1) | (Kg/mm2) | (10o/C) | (W/mk) | |

| Sicer-A | 3.81-3,84 | 360-400 | 4.0-5.0 | 1350-1450 | 7.0-8.0 | 18-20 |

| Sicer-SubA | 3.86-3,88 | 380-420 | 5.0-6.0 | 1450-1530 | 7.0-8.0 | 20-25 |

| Sicer-AZ | 5.65-5,75 | 900-1100 | 5.0-6.0 | 1400-1500 | 9.0-10.0 | 3-4 |

| Sicer-ZROX | 5.70-5,75 | 900-1100 | 8.0-9.0 | 1200–1250 | 9.0-10.0 | 1-2 |

| Sicer-ASC | 3.05-3.10 | 350-400 | 4.0-4.5 | 2000–2400 | 4.0-4.5 | 80--90 |

| Sicer-SN | 3.05-3.20 | 650-750 | 6.0-6.7 | 1650-1750 | 2.5-3.0 | 30--50 |

Lintho tsa Dewatering - AlOx

Aluminium oxide ea boleng bo holimo ho submiron 99% e ka sebelisoa ho mefuta e mengata ea lebelo la mochini ka katleho e ntle ka ho fetisisa ea litšenyehelo.

Max. Bolelele ~ 9000mm

Ho hanyetsa ho apara hantle

Bokhopo bo tlase

Ts'ebeliso e pharaletseng

Tlhokomelo e tlase

Theko e sebetsang

Ae fetisetsoa bakeng sa: thapo e felletseng ea terata tlasa 800m/min

Gravitation dewatering box tlas'a 1200m/min

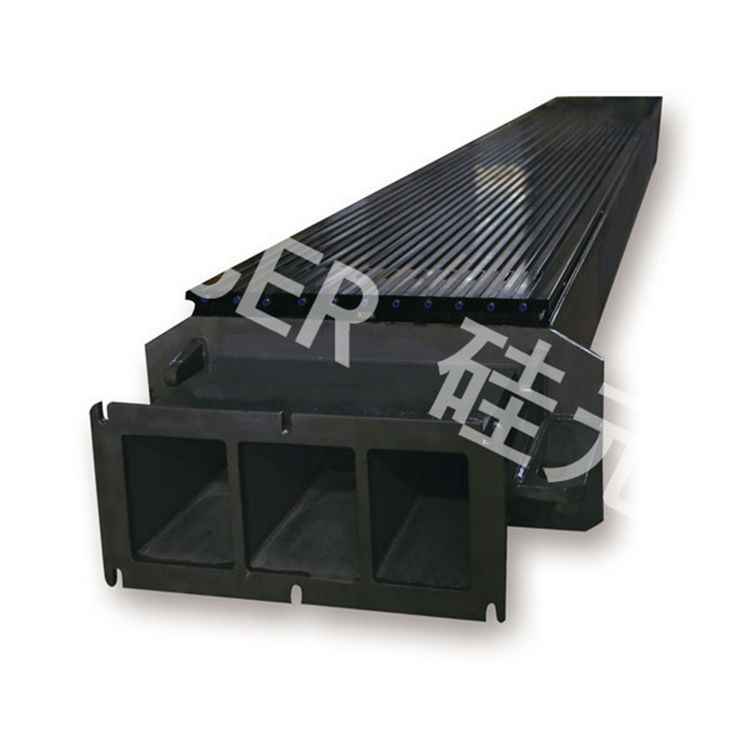

Dewatering Elements-SN

Lisebelisoa tsa ho tlosa metsi tsa SICER-SN li sebelisitse thepa e matla e phahameng joalo ka motheo, e koahetsoeng ka lirafshoa tsa boleng bo holimo tsa SiN e sa sebetseng. Ho nepahala ha eona ho phethahetseng le boleng bo botle ba machining bo netefalitse ho kenngoa ka mokhoa o sireletsehileng le ho nkeloa sebaka. Ka tlamahano e se nang moeli, ha ho senotlolo sa piano se ileng sa hlaha sekoahelong.

Lisebelisoa tsa boleng bo phahameng ba Si3N4

Ts'ebetso e tšepahalang ea nako e telele

Ho hanyetsa ho apara holimo

Ho nosetsa ho sa feleng

E etselitsoe: sekoaelo sa vacuum kapa karolo ea tobetsa tlas'a 1500m/min

Lintho tse Hlahisang metsi- ZA

Lintho tse Dewatering-ZROx

Tšireletso e betere ea maikutlo le ho lelefatsa bophelo ba eona

Khohlano e tlase ea khohlano

Boreleli le boleng bo ntlafetseng ba bokaholimo

E sebelisitsoe bakeng sa: karolo ea tobetsa tlas'a lebelo la mochine la 1000m / min

Lintho tsa Dewatering-AZ

Lintho tse bonahalang: Al2O3 le ZirO2

Ts'ebetso e tšepahalang ea nako e telele

Ho hanyetsa ho apara holimo

Mokelikeli o Sebetsang

Tšebeliso e tlase ea matla

E etselitsoe: sekoaelo sa vacuum kapa karolo ea tobetsa tlas'a 1500m/min