Sab saum toj Qib Tuam Tshoj Kub Kub Zirconia Ceramic Foam Lim rau Steel Foundries

Lus piav qhia luv luv:

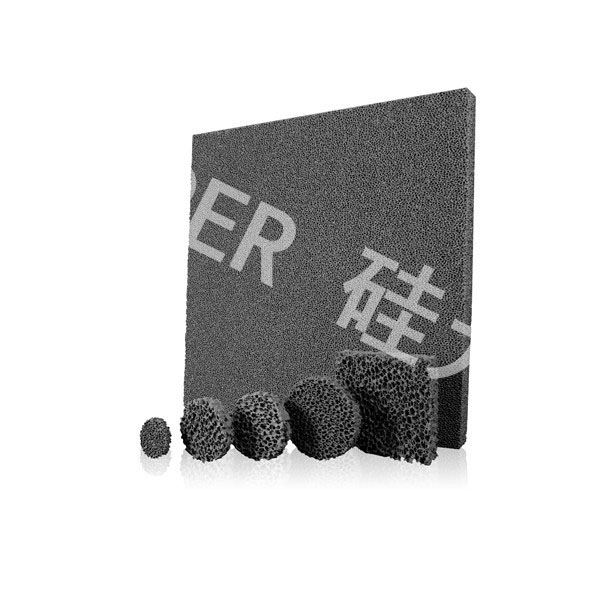

Raws li cov khoom lag luam zoo ntawm cov lim dej ceramic, SICER specilized hauv kev tsim cov khoom hauv plaub yam khoom, uas yog silicon carbide (SICER-C), aluminium oxide (SICER-A), zirconium oxide (SICER-Z) thiab SICER-AZ. Nws cov qauv tshwj xeeb ntawm peb-seem network tuaj yeem tshem tawm cov impurities ntawm cov hlau molten, uas tuaj yeem txhim kho cov khoom lag luam thiab microstructure. SICER ceramic lim tau siv dav hauv cov hlau tsis muaj hlau pom thiab kev lag luam casting. Nrog kev taw qhia ntawm kev xav tau ntawm kev lag luam, SICER ib txwm tsom mus rau R & D ntawm cov khoom tshiab.

Product Detail

Khoom cim npe

Peb muaj ib pab neeg ua haujlwm tau zoo los daws cov lus nug los ntawm cov neeg siv khoom. Peb lub hom phiaj yog "100% cov neeg siv khoom txaus siab los ntawm peb cov khoom zoo, tus nqi & peb pab neeg pabcuam" thiab txaus siab rau lub koob npe zoo ntawm cov neeg siv khoom. Muaj ntau lub Hoobkas, peb tuaj yeem muab ntau yam ntawm Sab saum toj Qib Tuam Tshoj High Temperature Zirconia Ceramic Foam Lim rau Steel Foundries, Peb zoo siab txais tos cov phooj ywg los ntawm thoob plaws lub ntiaj teb los koom tes nrog peb nyob rau hauv lub hauv paus ntawm kev pab mus sij hawm ntev.

Peb muaj ib pab neeg ua haujlwm tau zoo los daws cov lus nug los ntawm cov neeg siv khoom. Peb lub hom phiaj yog "100% cov neeg siv khoom txaus siab los ntawm peb cov khoom zoo, tus nqi & peb pab neeg pabcuam" thiab txaus siab rau lub koob npe zoo ntawm cov neeg siv khoom. Nrog ntau lub Hoobkas, peb tuaj yeem muab ntau yam ntawmCeramic Lim, Tuam Tshoj Ceramic Ua Npuas Ncauj, Tam sim no kev sib tw hauv daim teb no yog qhov hnyav heev; tab sis peb tseem yuav muab qhov zoo tshaj plaws, tus nqi tsim nyog thiab kev pabcuam siab tshaj plaws hauv kev sim ua kom tau txais lub hom phiaj yeej-yeej. "Hloov rau qhov zoo dua!" yog peb cov lus hais tias, "Lub ntiaj teb zoo dua yog ua ntej peb, yog li cia peb txaus siab rau nws!" Hloov rau qhov zoo dua! Koj puas npaj txhij?

Raws li cov khoom lag luam zoo ntawm cov lim dej ceramic, SICER specilized hauv kev tsim cov khoom hauv plaub yam khoom, uas yog silicon carbide (SICER-C), aluminium oxide (SICER-A), zirconium oxide (SICER-Z) thiab SICER-AZ. Nws cov qauv tshwj xeeb ntawm peb-seem network tuaj yeem tshem tawm cov impurities ntawm cov hlau molten, uas tuaj yeem txhim kho cov khoom lag luam thiab microstructure. SICER ceramic lim tau siv dav hauv cov hlau tsis muaj hlau pom thiab kev lag luam casting. Nrog kev taw qhia ntawm kev xav tau ntawm kev lag luam, SICER ib txwm tsom mus rau R & D ntawm cov khoom tshiab.

Ceramic ua npuas ncauj lim yog tsuas yog siv rau hauv kev pom ntawm txhuas, tooj liab, hlau, hlau alloys thiab hlau casting. Ceramic ua npuas ncauj lim muaj qhov ntim siab heev ntawm porosity- siab tshaj 90%, thiab thaj chaw siab heev rau ntxiab suav nrog. Nrog rau kev tiv thaiv zoo heev rau kev tawm tsam thiab corrosion daim ntawv molten hlau, cov ntxaij lim dej tuaj yeem tshem tawm cov kev sib koom ua ke, txo cov pa roj thiab muab cov laminar ntws, kom cov hlau lim tau huv dua nrog cov khoom zoo dua qub, cov khoom seem tsawg dua, thiab qhov tsis xws luag, tag nrho cov no ua rau kev ua haujlwm zoo dua. Nws redues qhov turbulence thaum lub sij hawm casting thiab tiv thaiv txawv teb chaws los ntawm nkag mus rau hauv lub casting.

Silicon Carbide Lim

| Hom | Cov khoom siv refractory |

| Khoom siv | SiC |

| Refractoriness (℃) | ≤1500 |

| Xim | Grey Dub |

| Qhov siab (ppi) | 10-60 |

| Loj | Customized |

| Cov duab | Square, Rectangle, Round thiab lwm yam. |

Silicon carbide lim yog tsim los ntawm cov khoom zoo silicon carbide micro hmoov raws li cov txheej txheem molding tshwj xeeb. Nws yog tsim rau hlau castings ntau lawm hauv qab 1500 ℃ vim nws zoo heev thermal stability thiab zoo thermal poob siab kuj.

Qhov zoo

•Zoo heev thermal stability

•Siab porosity

•Muaj peev xwm nqus tau zoo heev los txo cov kev suav nrog

•Ntau yam ntawm qhov loj me thiab qhov pore txoj kab uas hla

•Zoo thermal shock tsis kam

•Haum rau hlau castings ntau lawm hauv qab 1500 ℃

Ntsiab Specifications/Special Features

| Performance Parameter | |||

| Compress zog (MPa) | Porosity (%) | Qhov ceev (g / cm³) | Siv Temp ℃ |

| ≥1.2 | 80-87 : kuv | ≤0.5 | ≤1500 |

| Muaj peev xwm | |||

| Grey Hlau | 4 Kg/cm2 | Hlau hlau | 1.5Kg / cm2 |

Khoom Qhia

Aluminium Oxide Lim

| Hom | Cov khoom siv refractory |

| Khoom siv | Al2O3 |

| Refractoriness (℃) | ≤1350 |

| Xim | Dawb |

| Qhov siab (ppi) | 10-60 |

| Loj | Customized |

| Cov duab | Square, Rectangle, Round thiab lwm yam. |

Aluminium Oxide Lim

Aluminium oxide lim feem ntau yog siv rau hauv kev pom ntawm aluminium, aluminium alloy thiab molten hlau nyob rau hauv 1350 ℃, tuaj yeem daws cov teeb meem sab hauv thiab cov teeb meem rhiab nyob rau hauv cov khoom siv aluminium alloy thiab txo qhov tsis kam lees.

Tag nrho cov porosities ntawm PPI 10 txog PPI 60 tuaj yeem muab tau.

Lim hauv txhua qhov ntau thiab tsawg: 7x7x2 '', 9x9x2 '', 12x12x2''. 15 x 15 x 2', 17 x 17 x 2', 20 x 20 x 2', 23 x 23 x 2'.

Qhov zoo

•Eco-friendly ntau lawm txheej txheem

•Siab saum npoo muaj zog

•Ntau yam ntawm qhov loj me thiab qhov pore txoj kab uas hla

•Kev khiav hauj lwm zoo dua

•Tshem tawm kev suav nrog thiab txo tus nqi tsis lees paub

•Beveled npoo thiab compressible gasket

Ntsiab Specifications/Special Features

| Performance Parameter | ||||

| Hom | Compress zog (MPa) | Porosity (%) | Qhov ceev (g / cm³) | Siv Temp ℃ |

| SICER-A | ≥0.8 | 80-90 : kuv | 0.4 ~ 0.5 hli | 1260 |

| Specification thiab muaj peev xwm | ||||

| Loj (mm) | Kev khiav hauj lwm (kg / min) | Peev xwm (≤t) | ||

| 432 * 432 * 50 hli | 180-370 Nws | 35 | ||

| 508 * 508 * 50 (20') loj | 270-520 : kuv | 44 | ||

| 584 * 584 * 50 hli | 360-700 Nws | 58 | ||

Khoom Qhia

Zirconia Oxide Lim

| Hom | Cov khoom siv refractory |

| Khoom siv | ZrO2 |

| Refractoriness (℃) | ≤1750 |

| Xim | Daj |

| Qhov siab (ppi) | 10-60 |

| Loj | Customized |

| Cov duab | Square, Rectangle, Round thiab lwm yam. |

Khoom piav qhia

Zirconium oxide lim yog tsim los ntawm siab purity ziconia raws li cov txheej txheem ntau lawm. Nws yog tsim los siv rau hauv kev pom ntawm stainless hlau, carbon hlau thiab lwm yam kub alloy yaj hauv qab 1750 ℃, tuaj yeem txhim kho cov khoom tsim nyog tus nqi ntawm casts thiab txo pwm hnav.

Qhov zoo

•High purity zironia ua raw khoom

•Cov txheej txheem ntau lawm

•Ntau yam ntawm qhov loj me thiab qhov pore txoj kab uas hla

•Mechanical khoom zoo heev thiab tsis muaj slag

•Siab thermal shock kuj

•Zoo txo reoxidation thiab subsurface defect

•Zoo lim cov khoom tsis yog xim hlau, slag

•Txo cov pwm hnav thiab ua kom yooj yim rau lub rooj vag

Ntsiab Specifications/Special Features

| Performance Parameter | ||||

| Hom | Compress zog (MPa) | Porosity (%) | Qhov ceev (g / cm³) | Siv Temp ℃ |

| SICER-Z | ≥2.5 | 77-83 : kuv | ≤1.2 | ≤1750 |

| Muaj peev xwm | ||||

| Cov pa roj carbon steel | 1.5-2.5Kg / cm32 | Stainless hlau | 2.0-3.5Kg / cm2 | |

Khoom Qhia

Peb muaj ib pab neeg ua haujlwm tau zoo los daws cov lus nug los ntawm cov neeg siv khoom. Peb lub hom phiaj yog "100% cov neeg siv khoom txaus siab los ntawm peb cov khoom zoo, tus nqi & peb pab neeg pabcuam" thiab txaus siab rau lub koob npe zoo ntawm cov neeg siv khoom. Muaj ntau lub Hoobkas, peb tuaj yeem muab ntau yam ntawm Sab saum toj Qib Tuam Tshoj High Temperature Zirconia Ceramic Foam Lim rau Steel Foundries, Peb zoo siab txais tos cov phooj ywg los ntawm thoob plaws lub ntiaj teb los koom tes nrog peb nyob rau hauv lub hauv paus ntawm kev pab mus sij hawm ntev.

Qib SiabTuam Tshoj Ceramic Ua Npuas Ncauj, Ceramic Lim, Tam sim no kev sib tw hauv daim teb no yog qhov hnyav heev; tab sis peb tseem yuav muab qhov zoo tshaj plaws, tus nqi tsim nyog thiab kev pabcuam siab tshaj plaws hauv kev sim ua kom tau txais lub hom phiaj yeej-yeej. "Hloov rau qhov zoo dua!" yog peb cov lus hais tias, "Lub ntiaj teb zoo dua yog ua ntej peb, yog li cia peb txaus siab rau nws!" Hloov rau qhov zoo dua! Koj puas npaj txhij?