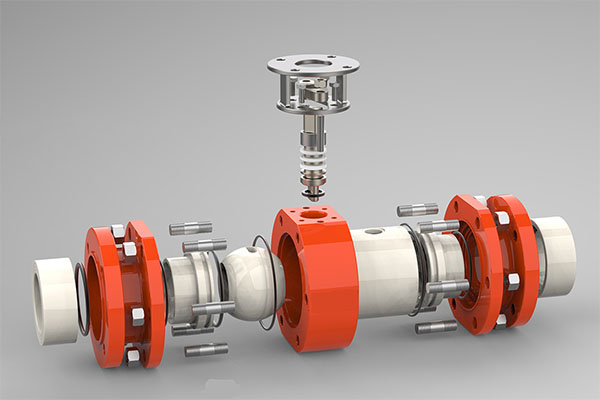

Ceramic li qub

Lus piav qhia luv luv:

1.Raws li kev ua haujlwm thiab qee qhov tshwj xeeb ua haujlwm ntawm lub twj tso kua mis plunger, SICER yuav tsim cov txheej txheem tshwj xeeb ceramic thiab cov qauv xaiv.

2.Ob qhov yoog raws thiab nruj foob tuaj yeem raug txiav txim rau ntau yam yuav tsum tau ua.

3.Paticular ceramic cov ntaub ntawv thiab cov khoom siv lubrication tus kheej tuaj yeem muab tau rau kev sib tw ntawm kev sib txhuam khub kom txo qis kev puas tsuaj ntxiv.

4. Hluav taws xob, pneumatic, thiab cov chaw taws teeb tswj tuaj yeem ua tiav nrog kev sib cais sib cais ntawm cov li qub.

Product Detail

Khoom cim npe

Taw qhia

1. Sicer muaj nplua nuj cov khoom siv ceramic, thiab tuaj yeem muab ntau yam khoom siv ceramic thiab cov khoom siv nws tus kheej lubricating;

2. Nyob rau tib lub sijhawm ua haujlwm, kev pabcuam lub neej ntawm ceramic valve yog ntau tshaj 5-10 npaug ntawm cov hlau zoo tib yam valve;

3. Siv lub ntsej muag tshwj xeeb ntawm cov khoom siv hluav taws xob ntawm lub pob valve los ua cov pob zeb ceramic kom ruaj khov thiab ruaj khov;

4. Kev nplua nuj nyob hauv valve ceramic khoom xaiv, tuaj yeem ua tau raws li qhov kev xaiv zoo tshaj plaws raws li kev ua haujlwm (siab, zaus, nruab nrab, thiab lwm yam);

5. Hluav taws xob / pneumatic / chaw taws teeb tswj kev hloov pauv, qhov zoo tshaj plaws ntawm cov qauv tsim thiab kev tsim khoom kom tsis txhob tawg sai thiab ua kom lub valve qhib thiab kaw dawb thiab ruaj khov ntawm torque;

6. Sicer tau tsim cov khoom siv tshiab ceramic valve, xws li ceramic C valve, ceramic slide valve thiab ceramic angle valve, thiab ua tiav lawv mus rau kev lag luam;

7. Dav siv nyob rau hauv ntau yam kua qaub thiab alkali kua, siab kub chav, av nkos, crude roj tsheb thauj mus los thiab cia system. Nws yog ib qho zoo tagnrho hloov rau titanium hlau valve thiab Monel valve nyob rau hauv muaj zog corrosion tej yam kev mob. Kaum tawm txhiab tus ceramic li qub ntawm ntau hom tau siv.

8. Kev pabcuam kev sib tham tsis tu ncua ua ntej thiab tom qab muag.

Daim ntawv thov Case

Qhov project loj tshaj plaws hauv ntiaj teb ib leeg-rau-roj project

Ib txoj haujlwm tshiab ntawm kev lag luam tshuaj lom neeg

Cov ntaub ntawv yooj yim

1. Raws li kev ua haujlwm thiab qee qhov tshwj xeeb ua haujlwm ntawm lub twj tso kua mis plunger, SICER yuav tsim tshwj xeeb ceramic txheej txheem thov thiab module xaiv.

2. Ob qho tib si saj zawg zog thiab nruj foob tuaj yeem raug txiav txim rau ntau yam yuav tsum tau ua.

3. Paticular ceramic cov ntaub ntawv thiab cov khoom siv lubrication tus kheej tuaj yeem muab rau kev sib tw ntawm kev sib txhuam khub kom txo qis kev puas tsuaj ntxiv.

4. Hluav taws xob, pneumatic, thiab cov chaw taws teeb tswj tuaj yeem ua tiav nrog kev sib cais sib cais ntawm cov li qub.

Khoom Qhia

Cov khoom siv ceramic sib txawv rau cov ntawv thov sib txawv.

1. Alumina (Al2O3) yog ib qho ntawm cov khoom siv hluav taws xob zoo tshaj plaws, nws muaj cov khoom zoo corrosion thiab abrasion tsis kam.

2. Zirconium (ZrO2) yog lub zog siab tshaj plaws thiab toughness ntawm chav tsev kub ntawm tag nrho cov engineered ceramics. Tab sis qhov ZrO2 no muaj kev txwv qhov kub thiab txias, Max kub yog 320 degC.

3. Silicon Nitride yog ib qho ntawm cov khoom siv ceramic tshwj xeeb tshaj yog siv rau cov ntawv thov kub, tshwj xeeb hauv vaj tse thiab cov khoom siv ceramic tso cai rau kev kub siab txog 950 degC.

4. Silicon Carbide yog cov khoom hardness tshaj plaws ntawm tag nrho cov engineered ceramics, nyob rau hauv lwm yam lus SiC hardness ntawm pob zeb diamond. Tab sis tsis tshua muaj pob txha toughness ntawm SiC yog qhov tsis muaj zog loj rau cov khoom siv ceramic, nws yooj yim tawg.